.png)

.png)

.png)

MISA’S welding rotators and turning rolls are designed to support and rotate cylindrical workpieces, Wuch as pipes, tanks, shells and pressure vessels, wind towers during welding and fabrication processes. These machines enhance precision, safety, and productivity by allowing consistent rotation for high-quality welds and easy access to all areas of the workpiece.

MISA’S models feature robust construction to handle heavy loads with stability, offering adjustable speed control for precise operation. With options for both self-aligning and adjustable designs, our welding rotators can accommodate a variety of diameters and weights, making them versatile for i ndustries like oil and gas, shipbuilding, and steel fabrication.

If you are looking for innovative welding rotators for heat exchangers and pressure vessels. In this blog, we will give you an idea on the type of welding rotator to use for pressure vessels and heat exchangers.

Whether you’re in the oil and gas sector, power generation, pharmaceutical, automotive, or even in renewable energy, you’re in for a treat! You’ll no longer need to dig through thousands of documents to find the best welding rotators!

MISA choose the best wheel material suit for your vessel or pipe application,you can choose press in polyurethane wheels, rubber wheels or steel wheels,even knurling on the steel wheels to increase friction.

MISA customize the suitable power supply for your machine,from 110v to 600v, we know your Industrial input voltage and electrical requirements. And different standard, such as the safety rules , cable color,etc.

MISA provide wired hand pendant with 25ft long control cable or wireless hand pendant with 300ft working area. Foot switch can be as another options for manual spot welding.

MISA can assembly manual travel trolley or motorized under the rotator frame, realize transfer the vessel on rail , create a more efficient workshop, reduce the use of overhead crane.

MISA provide explosion proof solution for sand blasting , painting and chemical working condition. Double layered electrical control cabinet ensures safety.

MISA can provide other special requirements, such as add the stop roller at the end of the rotator frame to prevent the vessel movement. Choose different gearbox ratio to get different rotating & travelling speed.

In today’s date and time, welding automation is considered the future of work. The welding industry is one of the first industries that experienced and felt its overall effects.

While there’s currently endless options for automated welding, we’ll give you few of the most crucial, we’ll talk about what welding automation really is, how it can help your overall processes.

In modern industrial fabrication, welding rotators—also known as tank turning rolls or pipe rotators—have become indispensable for welding cylindrical workpieces. Whether it’s a pressure vessel, storage tank, or wind tower section, these machines enable precise, consistent, and efficient welding by automatically rotating the workpiece during the process.

Manual welding of large cylindrical structures presents numerous challenges—uneven welds, high labor intensity, and inconsistent results. Welding rotators eliminate these limitations by maintaining a controlled and uniform rotation, ensuring optimal weld penetration and alignment. They also improve operator safety by reducing the need for manual handling of heavy materials.

At MISA, we design and manufacture advanced welding rotators and automatic tank turning rolls that meet the rigorous demands of global industries. Each unit is built with precision, reliability, and versatility in mind, supporting projects ranging from light pipe welding to heavy industrial fabrication. This guide will help you understand how welding rotators work, their types, benefits, applications, and how to select the ideal model for your production line.

By the end of this comprehensive guide, you will gain not only a clear understanding of welding rotators but also practical insights into how MISA's solutions can elevate your welding performance, productivity, and overall project efficiency.

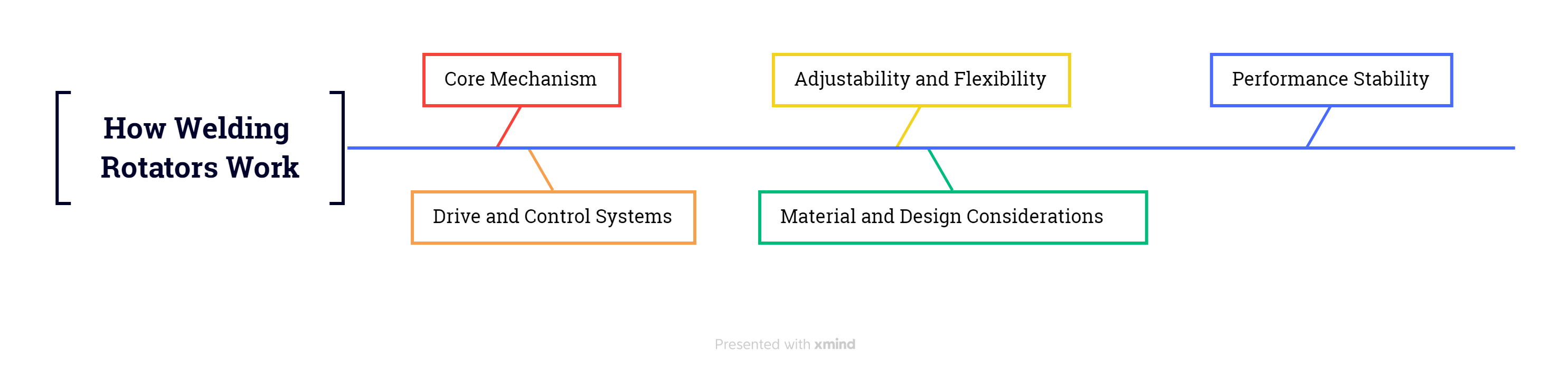

Welding rotators function by supporting and rotating cylindrical workpieces—such as pipes, tanks, or pressure vessels—during the welding process. The principle behind their operation is relatively straightforward yet highly effective: by maintaining a constant rotation, welders can perform smooth circumferential welds with uniform heat distribution and minimal distortion.

A typical welding rotator consists of a powered drive unit and one or more idler units. The drive unit uses a motorized roller system to rotate the workpiece through direct frictional contact between the rollers and the vessel surface. The idler units, which can be adjusted along the base frame, provide additional support and stability to the workpiece. Together, they ensure smooth, continuous, and controlled rotation throughout the welding cycle.

Modern welding rotators are equipped with advanced drive and control systems that allow precise adjustment of rotation speed and torque. Most high-end models use inverter-controlled AC or DC motors for stepless variable speed control, ensuring consistent rotation even under varying loads. The control panel typically features a potentiometer or digital interface for fine-tuning the rotation speed according to the welding process requirements.

This precise control is particularly important for automated or semi-automatic welding systems. For instance, when paired with welding manipulators or column and boom systems, MISA rotators synchronize seamlessly to maintain perfect weld travel speed and positioning. This coordination results in high-quality, repeatable welds that meet stringent industrial standards.

Welding rotators come with either fixed or self-aligning roller systems. Self-aligning rotators automatically adjust the roller angle and spacing to accommodate different workpiece diameters—ranging from small pipes to large industrial tanks—without requiring manual intervention. This not only saves setup time but also enhances safety by reducing the need for physical adjustments during operation.

The quality and material of the rollers significantly influence performance and longevity. Heavy-duty rotators often feature steel or polyurethane rollers. Polyurethane rollers are ideal for delicate or coated surfaces as they prevent scratching or deformation, while steel rollers provide superior durability for heavy vessels. At MISA, all rollers are precision-machined and dynamically balanced to ensure vibration-free rotation and maximum service life.

Maintaining consistent rotation speed is critical for achieving defect-free welds. Fluctuations in speed can cause uneven weld penetration, spatter, or undercuts. MISA's welding rotators incorporate intelligent load-sensing systems that automatically compensate for changes in torque and resistance, keeping the rotation stable even with eccentric or unevenly loaded workpieces. This advanced engineering ensures consistent weld quality under all working conditions.

In essence, a welding rotator is more than just a rotating stand—it is a precision tool that enhances automation, safety, and weld quality. With advanced control systems, high-performance rollers, and durable construction, MISA's rotators deliver outstanding performance across diverse welding environments.

Welding rotators play a transformative role in industrial fabrication by improving weld precision, operator safety, and overall productivity. Whether in heavy manufacturing or light fabrication, they offer a wide range of tangible benefits that make them essential in modern welding automation systems.

| Advantage | Description |

|---|---|

| 1. Superior Weld Quality and Consistency | Welding rotators maintain uniform rotational speed, ensuring consistent heat input and eliminating irregularities like undercuts or incomplete fusion. This results in stronger, more uniform welds that comply with AWS and ISO standards. They also minimize manual repositioning, improving repeatability and precision—especially critical in industries such as aerospace and pressure vessel fabrication. |

| 2. Enhanced Productivity and Reduced Cycle Time | Automating rotation shortens welding cycles, allowing steady arc travel and continuous operation. This boosts production efficiency by up to 30–40%, helping manufacturers meet tight schedules while maintaining top-quality welds. |

| 3. Improved Operator Safety | Welding rotators eliminate manual handling of large tanks or pipes, reducing strain and accident risks. Operators can control the rotation remotely, while features such as emergency stop and overload protection (as found in MISA’s systems) enhance operational safety. |

| 4. Reduced Operator Fatigue | Automated rotation allows welders to maintain ergonomic working positions and focus on precision instead of repositioning heavy workpieces, minimizing physical fatigue during long shifts. |

| 5. Versatility Across Workpiece Sizes | Adjustable or self-aligning rollers enable modern welding rotators to handle various diameters and weights—from small pipes to massive pressure vessels—reducing setup time and fixture requirements. |

| 6. Integration with Automated Welding Systems | Welding rotators integrate with manipulators, column and boom systems, or positioners to create fully automated welding cells capable of precise circumferential welds. This makes them essential for Industry 4.0–ready manufacturing setups. |

| 7. Cost-Effectiveness and ROI | Despite the initial investment, welding rotators deliver high ROI by increasing productivity, reducing rework, and lowering labor costs. Many companies recover costs within a year due to improved efficiency and energy savings. |

| 8. Improved Safety Compliance and Quality Control | In industries like oil & gas, nuclear, and aerospace, rotators help meet strict safety and quality standards by reducing human error and ensuring uniform, certifiable welds supported by automated monitoring systems. |

In summary, welding rotators not only simplify the welding process but also enhance overall production performance, safety, and profitability. At MISA, our welding rotators embody these advantages through precision engineering, advanced automation, and robust construction—making them a valuable investment for every forward-thinking manufacturer.

Welding rotators come in several configurations, each designed to serve specific workpiece sizes, production volumes, and automation requirements. Understanding the differences between these types is essential when choosing the most suitable system for your application. MISA offers three main series of welding rotators — MCR Conventional Rotators, MSAR Self-Aligning Rotators, and MSR Pipe Spool Rotators — providing comprehensive coverage for diverse industrial welding needs.

The MCR Series represents MISA's line of traditional, manually adjustable conventional welding rotators. These systems feature independent drive and idler units with manually adjustable wheel centers, allowing operators to adapt to different vessel diameters quickly and accurately. They are ideal for workshops that handle a wide range of cylindrical components and prefer direct control over setup adjustments.

Each MCR rotator combines mechanical precision with structural durability, ensuring stable rotation under heavy loads. The design features adjustable steel rollers, heavy-duty frames, and inverter-based variable speed control. These models are best suited for applications such as pressure vessel fabrication, tank manufacturing, and general industrial welding lines.

The MSAR Series is MISA's flagship line of self-aligning welding rotators, engineered for automatic adaptation to different vessel diameters without manual adjustment. The self-aligning mechanism allows the rollers to automatically pivot and reposition according to the workpiece size, maintaining perfect alignment and pressure distribution.

These models are ideal for automated and high-volume production environments where speed, consistency, and safety are top priorities. The MSAR Series features polyurethane-coated rollers to prevent surface damage and a high-precision inverter control system for smooth, stepless speed adjustment. Integrated overload protection ensures long-term reliability even under continuous heavy-duty operation.

Common applications include wind tower sections, large storage tanks, pressure vessels, and heavy pipelines. The self-aligning feature reduces setup time by up to 70% compared to conventional models, significantly enhancing production efficiency.

The MSR Series focuses on pipe spool and small-diameter workpieces, offering a compact yet powerful solution for workshops dealing with specialized welding tasks. These rotators use a scissor-type structure for quick adjustment and feature polyurethane wheels for excellent surface protection and grip.

The MSR-5 is particularly useful in pipe fabrication shops, spool assembly lines, and repair facilities where agility and accuracy are essential. Its small footprint and ergonomic design make it easy to integrate into existing production lines or use as a mobile auxiliary system.

Each MISA series caters to different operational requirements:

By offering this comprehensive range, MISA ensures that every customer can find the optimal balance of capacity, precision, and control for their specific production needs. Whether your goal is maximum automation or flexible manual operation, MISA’s welding rotators provide a reliable and scalable solution for every welding challenge.

Welding rotators are essential equipment across a wide range of heavy fabrication and manufacturing industries. They enable efficient, high-precision welding of cylindrical or conical components, significantly improving productivity, safety, and weld quality. MISA’s three series—MCR, MSAR, and MSR—are engineered to serve different application needs, ensuring the right match for every industrial setting.

Beyond traditional industries, MISA’s engineering team also provides customized welding rotator solutions for specialized applications. Whether for large-diameter stainless steel reactors in the pharmaceutical industry, cryogenic vessels for LNG systems, or artistic metal structures, MISA can design and manufacture rotators that precisely fit the client’s operational and dimensional requirements.

This flexibility, combined with robust mechanical engineering and international safety compliance, makes MISA a trusted partner for fabrication projects worldwide.

From pressure vessel workshops to offshore fabrication yards, MISA welding rotators continue to support global industries with reliable, high-performance solutions that elevate production efficiency and weld precision.

When selecting welding equipment, reliability, precision, and technical expertise matter. MISA has established itself as a trusted global manufacturer of welding rotators, tank turning rolls, and automatic welding solutions, providing advanced systems that meet the diverse needs of modern fabrication industries. Our goal is to help customers achieve flawless, efficient, and repeatable welds—no matter the size or complexity of their projects.

Each MISA welding rotator is built with precision-engineered components and robust mechanical design. Whether it’s the MCR Conventional Series, MSAR Self-Aligning Series, or MSR Pipe Spool Series, our machines undergo strict quality testing to ensure superior performance and long-term reliability in demanding environments.

MISA integrates variable-frequency drives (VFDs), digital control panels, and synchronized rotation systems for seamless coordination during the welding process. These advanced controls guarantee smooth rotation, adjustable speed, and consistent welding parameters—critical for achieving defect-free welds in industries like energy, pressure vessel fabrication, and shipbuilding.

No two welding projects are the same. MISA provides customized solutions based on load capacity, workpiece geometry, and automation level. Whether you require a heavy-duty rotator for wind tower sections or a light-duty spool rotator for small pipe assemblies, our engineering team ensures that each system perfectly fits your operational requirements.

Safety is at the heart of every MISA design. From overload protection and emergency-stop systems to high-strength rollers and industrial-grade materials, our welding rotators are built to deliver years of reliable performance with minimal maintenance. Every detail is designed to reduce downtime and ensure operator safety.

With a strong international presence and responsive technical team, MISA supports clients worldwide—from initial consultation and installation to after-sales service and spare parts supply. Our commitment to customer success extends beyond machinery—we provide lasting partnerships built on trust and performance.

Welding rotators play a pivotal role in modern fabrication, enabling manufacturers to improve weld quality, enhance productivity, and maintain safety standards across industries. Whether in pressure vessel manufacturing, pipeline welding, or heavy steel fabrication, the right welding rotator can transform your production efficiency and precision.

By choosing MISA, you are investing in a brand known for engineering innovation, durability, and customer-oriented service. Our full range of automatic welding rotators and tank turning rolls are designed to help you achieve consistent, high-quality welds with confidence.

Explore MISA Welding Rotators today or contact our team for a tailored solution that fits your project needs.

A welding rotator is a device designed to rotate cylindrical workpieces during welding or fabrication. It ensures consistent rotation, allowing for uniform welds. Typically, it consists of powered rollers, a drive motor, and a control system that adjusts rotation speed based on workpiece size and welding requirements.

Welding rotators improve weld quality, reduce labor costs, and increase safety. They allow for precise, continuous rotation, making it easier to weld large or heavy cylindrical structures, such as tanks, pipes, and pressure vessels.

Key factors include load capacity, workpiece diameter, type of rotation (driven vs. idle rollers), and application environment. Always consider the weight of your workpiece and whether single or double rotator setups are needed.

Common types include:

- Self-aligning rotators – automatically adjust to different diameters.

- Fixed-position rotators – for consistent, repetitive operations.

- Hydraulic or motor-driven rotators – for heavy-duty industrial use.

Welding rotators are widely used in:

- Oil and gas tank fabrication

- Pressure vessel manufacturing

- Pipe and pipeline construction

- Heavy machinery and steel fabrication

Regular maintenance includes lubrication of rollers and bearings, checking motor and gearbox conditions, and inspecting alignment. Proper maintenance extends service life and ensures consistent welding quality.

MISA welding rotators offer precise speed control, high load capacity, and robust construction. Our models are designed for versatility across industries, with strong after-sales support and customizable options.