Unlocking Welding Excellence: A Comprehensive Guide to Welding Positioners for Enhanced Efficiency and Precision

Meta Description:

Discover the transformative role of welding positioners in welding processes. From understanding their functionality and components to exploring applications and safety measures, this guide explores how welding positioners from MISA Welding, with over two decades of excellence, can elevate your welding projects with innovation, customization, and top-notch quality.

Contents

- Unlocking Welding Excellence: A Comprehensive Guide to Welding Positioners for Enhanced Efficiency and Precision

- Introduction

- What is a Welding Positioner?

- How Does a Welding Positioner Work?

- Main Components of a Welding Positioner:

- Types of Welding Positioners Available in the Market:

- What Safety Measures Should Be Taken When Using Welding Positioners?

- What Maintenance Practices Are Recommended for Welding Positioners?

- Are There Specialized Welding Positioners for Specific Industries?

- How Can Welding Positioners Improve Workflow Efficiency?

- Do Welding Positioners Have Environmental Benefits in the Welding Process?

- Where to Locate Premium Welding Positioner

- Conclusion

Introduction

Welding positioners, the unsung heroes of the welding industry, play a pivotal role in enhancing efficiency, precision, and overall quality in welding processes. Understanding what a welding positioner is, how it functions, its components, and its diverse applications is crucial for welders and industry professionals alike. In this comprehensive guide, we delve into the intricacies of welding positioners, shedding light on their significance, types, applications, and the myriad ways they contribute to elevating welding projects to new heights.

What is a Welding Positioner?

A welding positioner is an indispensable tool in the field of metal fabrication and welding, streamlining the welding process and significantly improving the overall efficiency and quality of welds. This specialized equipment serves as a pivotal component in various industries, from automotive manufacturing to construction. Here are key points to understand about welding positioners:

- Manipulation and Orientation: Welding positioners are designed to manipulate the orientation of workpieces, allowing for precise control over the welding process. This manipulation is crucial for achieving optimal weld quality.

- Secure Workpiece Holding: One of the primary functions of a welding positioner is to securely hold the workpiece in place. This ensures stability during welding, preventing any unwanted movement that could compromise the integrity of the weld.

- Movement and Rotation: Welding positioners enable controlled movement and rotation of the workpiece. This capability is essential for accessing different angles and positions, making it easier for welders to reach intricate areas and achieve uniform welds.

- Fixed Position Maintenance: By using a welding positioner, welders can maintain a fixed position relative to the welding torch. This stability is critical for consistency in weld quality and helps reduce the likelihood of errors or defects.

- Enhanced Efficiency: The ability to manipulate, hold, and rotate workpieces with a welding positioner enhances the overall efficiency of the welding process. Welders can complete tasks more quickly and with greater precision, ultimately saving time and resources.

- Improved Weld Quality: The optimized welding position provided by a welding positioner contributes to improved weld quality. Welders can focus on achieving the desired penetration and fusion, resulting in stronger and more reliable welds.

- Versatility: Welding positioners come in various sizes and configurations, catering to the diverse needs of different welding applications. This versatility makes them adaptable to a range of projects across industries.

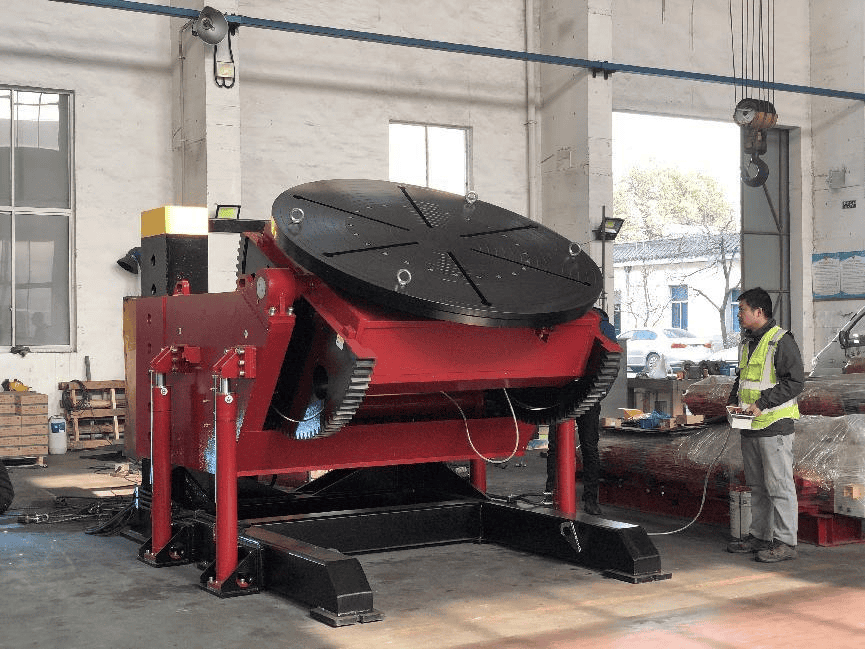

How Does a Welding Positioner Work?

Welding positioners play a crucial role in the machine industry, facilitating efficient and precise welding processes. These sophisticated machines operate through a combination of secure clamping mechanisms and controlled rotational and tilting movements. The key features and working principles of welding positioners include:

- Workpiece Clamping: Welding positioners are equipped with robust clamping systems that securely hold the workpiece in place during the welding operation. This ensures stability and accuracy throughout the welding process.

- Rotational Movements: One of the primary functions of welding positioners is to provide controlled rotational movements to the workpiece. This rotation is programmable, allowing welders to adjust the speed and direction based on the specific requirements of the welding project. This capability is essential for achieving uniform and consistent welds.

- Tilting Movements: In addition to rotation, welding positioners offer controlled tilting movements. This feature allows welders to position the workpiece at optimal angles for various welding scenarios, such as flat, overhead, horizontal, or vertical welds. The ability to tilt the workpiece enhances flexibility and accessibility during welding.

- Programmable Functionalities: Welding positioners are equipped with programmable controls, enabling welders to tailor the machine’s rotation speed, direction, and tilt angles according to the unique specifications of each welding project. This customization capability enhances precision and efficiency in the welding process.

- Enhanced Operator Safety: By automating the movement of the workpiece, welding positioners contribute to improved operator safety. Welders can focus on the welding technique and quality of the weld, while the machine takes care of the controlled movements, reducing the risk of human error and fatigue.

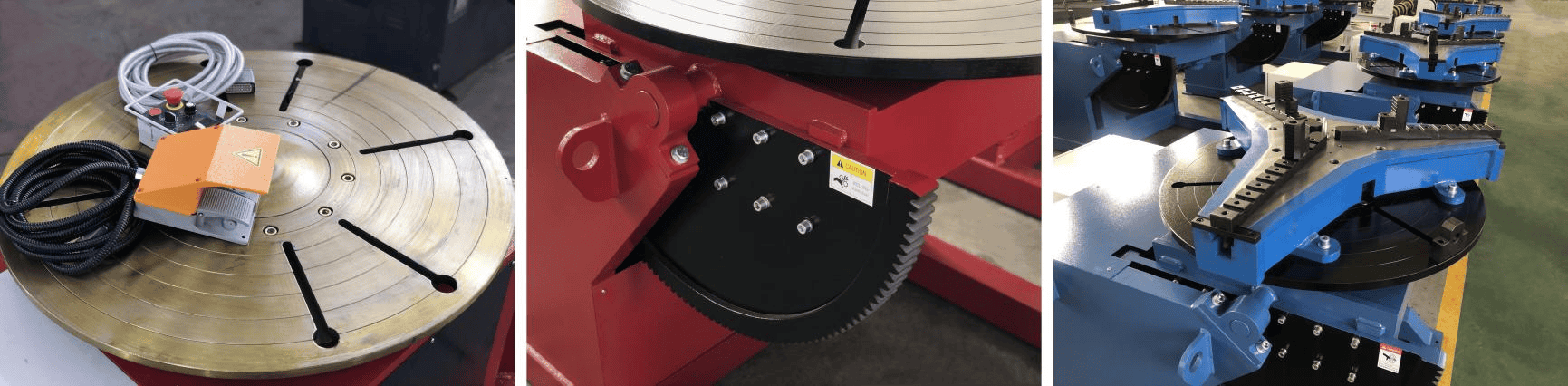

Main Components of a Welding Positioner:

In the machine industry, a welding positioner is a crucial tool that enhances efficiency and precision in welding processes. Understanding its main components is essential for maximizing its utility:

- Base:

- Function: The base serves as the foundation of the welding positioner, providing stability and support.

- Importance: A stable base ensures that the positioner can handle the weight and torque generated during the welding process, contributing to overall safety and accuracy.

- Chuck or Jaws:

- Function: The chuck or jaws are mechanisms designed to securely hold the workpiece in place during welding.

- Importance: A firm grip on the workpiece is essential to prevent any movement or misalignment during the welding operation, ensuring precise and uniform welds.

- Rotation Mechanism:

- Function: This component allows for controlled rotation of the workpiece, facilitating even exposure of the weld seam to the welding arc.

- Importance: Controlled rotation ensures uniform distribution of heat and weld material, resulting in consistent weld quality and minimizing the likelihood of defects.

- Tilting Mechanism:

- Function: The tilting mechanism enables controlled tilting or angling of the workpiece, providing flexibility in positioning for different welding angles.

- Importance: This feature is crucial for achieving optimal access to various welding joints, improving the welder’s ergonomics, and enhancing the overall efficiency of the welding process.

- Control Panel:

- Function: The control panel serves as the interface for programming and adjusting positioner settings, including rotation speed, tilt angle, and other parameters.

- Importance: A user-friendly control panel enhances the operator’s ability to customize and control the welding process, allowing for adaptability to different welding requirements and ensuring precision in the final weld.

Understanding and effectively utilizing these main components of a welding positioner can significantly contribute to the success of welding operations in the machine industry, promoting efficiency, safety, and high-quality welds.

Types of Welding Positioners Available in the Market:

In the dynamic field of the machine industry, various types of welding positioners play a crucial role in enhancing efficiency, precision, and safety in welding processes. Understanding the available options is essential for professionals seeking optimal solutions for their specific applications.

- 2-Axis Weld Positioners:

- Basic positioners designed to move in two axes (horizontal and vertical).

- Minimize vibrations, providing a stable platform for welding operations.

- Ideal for workpieces that require controlled movement in two dimensions.

- Multi-Axis Weld Positioners:

- Versatile positioners capable of moving in multiple axes, offering increased flexibility.

- Suitable for applications that involve tilting and angling of workpieces.

- Enhance the range of motion, accommodating complex welding requirements.

- Tailstock or Headstock Weld Positioners:

- Specifically designed for supporting rectangular workpieces that require support on both ends.

- Provide stability and balance during welding processes, ensuring uniform welds.

- Ideal for workpieces with elongated shapes that demand additional support.

- Turning Rolls or Welding Rotators:

- Specialized positioners designed for rotating cylindrical workpieces during welding.

- Ensure even welding along the entire circumference of the cylindrical object.

- Improve efficiency by eliminating the need for manual rotation, especially in long welding seams.

Professionals in the machine industry must carefully consider the specific requirements of their welding projects when selecting positioners. Whether it’s the simplicity of 2-axis movement or the versatility of multi-axis options, the right choice contributes significantly to the overall success and quality of welding operations. Tailoring the selection to the unique characteristics of the workpiece ensures optimal performance and adherence to industry standards.

What Safety Measures Should Be Taken When Using Welding Positioners?

Safety is a top priority when utilizing welding positioners, and several key measures should be observed. Operators must undergo proper training to handle the equipment safely. Regular inspections of the welding positioners are essential to identify and address any potential issues promptly. Ensuring the secure clamping of workpieces prevents accidents during the welding process, and adherence to safety guidelines specific to the welding processes being employed is crucial. The following bullet points provide a detailed explanation of these safety measures:

- Operator Training: Thorough training programs should cover the operation of welding positioners, safety protocols, and emergency procedures. This ensures that operators have the necessary skills and knowledge to handle the equipment safely.

- Equipment Inspections: Regular inspections, including visual checks and testing of critical components, help identify any wear, damage, or malfunction. This proactive approach allows for timely maintenance and prevents potential hazards.

- Secure Clamping: Properly securing workpieces is fundamental to preventing accidents. Inadequate clamping can lead to instability during welding, posing risks to both the operator and the equipment.

- Adherence to Safety Guidelines: Different welding processes have specific safety guidelines. Operators must strictly adhere to these guidelines to mitigate risks associated with the chosen welding method.

What Maintenance Practices Are Recommended for Welding Positioners?

Maintenance practices play a crucial role in ensuring the longevity and reliable performance of welding positioners. The following bullet points outline recommended maintenance practices:

- Lubrication: Regularly lubricating moving parts prevents friction-related wear and ensures smooth operation.

- Electrical Component Inspection: Checking and maintaining electrical components, such as controls and wiring, is essential to prevent malfunctions and ensure safety.

- Calibration: Regular calibration of rotation and tilt mechanisms maintains accuracy and precision in positioning, contributing to the quality of the welding output.

- Prompt Repairs: Identifying and addressing issues promptly is crucial to prevent further damage and downtime. Regular maintenance schedules and immediate repairs of identified problems are essential.

Are There Specialized Welding Positioners for Specific Industries?

Welding positioners can be customized for specific industries, such as shipbuilding, aerospace, and energy. This customization ensures optimal performance in specialized applications. The following bullet points provide more details on specialized welding positioners:

- Industry-Specific Customization: Welding positioners can be tailored to meet the specific requirements of different industries, incorporating features that enhance performance in specialized applications.

- Shipbuilding: Positioners designed for shipbuilding may have unique features to handle the size and weight of ship components efficiently.

- Aerospace: Customizations for aerospace applications may include precision controls and specialized fixtures to meet the stringent requirements of aerospace welding.

- Energy Sector: Welding positioners for the energy sector may be equipped to handle large and heavy components used in the construction of power plants and other energy-related infrastructure.

How Can Welding Positioners Improve Workflow Efficiency?

Welding positioners play a pivotal role in enhancing workflow efficiency within the machine industry, offering a myriad of benefits that contribute to improved productivity and consistent weld quality.

- Consistent Weld Quality: One of the primary advantages of welding positioners is their ability to ensure uniform and precise welds. By providing a controlled and stable environment for welding, these devices minimize the risk of inconsistencies that may arise from manual repositioning of workpieces. This consistency is crucial for maintaining high-quality welds, especially in intricate or critical applications.

- Reduced Downtime: Welding positioners significantly reduce the time spent on manual repositioning of workpieces. The automated rotation and tilting capabilities of these machines streamline the welding process, minimizing downtime associated with repositioning tasks. This not only increases overall efficiency but also allows operators to focus on other aspects of the welding process, leading to a more streamlined and time-effective workflow.

- Enhanced Operator Productivity: The automation provided by welding positioners reduces the physical strain on operators, mitigating operator fatigue. By handling the repositioning tasks automatically, these devices enable operators to concentrate on monitoring and optimizing the welding parameters. This results in improved operator productivity, as they can allocate their time and energy more effectively, ultimately contributing to a smoother and more efficient workflow.

In summary, welding positioners are indispensable tools in the machine industry, offering a trifecta of benefits: consistent weld quality, reduced downtime, and enhanced operator productivity. These advantages collectively contribute to a more efficient and streamlined welding process, ensuring high-quality results while optimizing resource utilization.

Do Welding Positioners Have Environmental Benefits in the Welding Process?

Welding positioners contribute to environmental benefits in the welding process through several mechanisms. The following bullet points elaborate on the environmental advantages of using welding positioners:

- Reduced Welding Fumes: Stationary welding positions minimize the dispersion of welding fumes, creating a safer and healthier working environment.

- Energy Efficiency: Optimal welding conditions facilitated by welding positioners contribute to reduced energy consumption, promoting efficiency and sustainability.

- Enhanced Precision: The precision offered by welding positioners minimizes material wastage, contributing to resource conservation and sustainability in the welding process.

Where to Locate Premium Welding Positioner

When seeking top-tier positioners in the market, it’s essential to explore options that balance quality and cost-effectiveness. Among the prominent regions for such equipment, Asia, particularly China, stands out, and MISA Welding emerges as a trusted supplier of high-quality positioners. Here are key reasons why MISA Welding is a preferred choice in the realm of positioners:

- Global Accessibility: MISA Welding operates on a global scale, ensuring that their premium positioners are available to customers worldwide.

- Industry Expertise: Boasting over two decades of industry experience, MISA Welding brings extensive knowledge to the forefront, guaranteeing that their positioners meet the highest standards.

- Comprehensive Solutions: MISA Welding takes a holistic approach to positioning equipment, offering comprehensive solutions that address diverse needs. This ensures that their positioners are versatile, catering to a wide range of applications.

- Quality Assurance: MISA Welding’s dedication to quality is evident in their products. Stringent quality control measures are implemented to ensure the dependability and longevity of their positioners.

- Engineering Excellence: With a team of seasoned engineers, MISA Welding actively contributes to the design, development, and ongoing enhancement of their positioning equipment. This ensures alignment with the latest technological advancements in the industry.

- Optimal Efficiency: MISA Welding’s positioners are designed for peak efficiency, enhancing the overall productivity of positioning processes and contributing to high-quality outcomes.

- Customer-Centric Support: Prioritizing customer satisfaction, MISA Welding provides exceptional customer support services. This encompasses assistance with product selection, technical guidance, and comprehensive after-sales support.

Conclusion

In the realm of the machine industry, welding positioners stand as pivotal assets, constituting a foundational element in the welding landscape. Beyond the evident advantages of heightened efficiency and precision, these apparatuses boast versatility and adaptability that renders them indispensable across diverse welding applications. Their integration capabilities not only streamline the welding process but also enhance overall project outcomes.

Whether you operate on a modest scale as a fabricator or wield industrial might as a powerhouse, embracing the technological strides in welding positioners proves instrumental in propelling your welding endeavors to unprecedented levels of success. In essence, these machines transcend mere tools; they embody the essence of progress and innovation, shaping the future trajectory of the welding industry.

Pingback: overnight pharmacy 4 u cialis

Pingback: cheap viagra generic 100mg

Pingback: online viagra cheap

Pingback: where to buy viagra with paypal

Pingback: viagra prescription medicine

Pingback: viagra 1000mg

Pingback: cialis over the counter at walmart

Pingback: cialis coupon 2019

Pingback: buy cialis with dapoxetine in canada

Pingback: cheap cialis free shipping

Pingback: gabapentin ototoxic

Pingback: bactrim parvovirose

Pingback: metronidazole toxoplasmosis

Pingback: nolvadex apotek

Pingback: aciclovir valtrex

Pingback: can you iv lyrica

Pingback: glucophage cravings

Pingback: lisinopril ramipril

Pingback: lasix ards

Pingback: 0.75 semaglutide

Pingback: side effects of semaglutide injections

Pingback: trulicity and rybelsus

Pingback: generic brand of zoloft

Pingback: metronidazole covers

Pingback: can i take cephalexin for a sinus infection

Pingback: cymbalta and lyrica

Pingback: viagra generic discount

Pingback: can i have a glass of wine when im taking escitalopram

Pingback: azithromycin metabolism

Pingback: does keflex smell bad

Pingback: duloxetine vs prozac

Pingback: does fluoxetine cause sleeplessness

Pingback: gabapentin snortable

Pingback: lexapro diarrhea

Pingback: can i take cephalexin if allergic to penicillin

Pingback: ciprofloxacin vs doxycycline

Pingback: bactrim dosage for sinus infection

Pingback: how long after taking bactrim can i breastfeed

Pingback: amoxicillin and potassium clavulanate

Pingback: effexor mechanism of action

Pingback: flexeril and hydrocodone

Pingback: how long does cozaar stay in your system

Pingback: buy ddavp drops

Pingback: what is depakote used for

Pingback: diltiazem side effect

Pingback: how to get citalopram out of your system faster

Pingback: is contrave covered by insurance

Pingback: flomax cramps

Pingback: augmentin for sinusitis

Pingback: ezetimibe atorvastatin merck

Pingback: diclofenac potassium side effects

Pingback: aripiprazole overdose

Pingback: how long does amitriptyline stay in your system

Pingback: allopurinol 300

Pingback: naproxen and aspirin

Pingback: does celexa cause weight gain

Pingback: bupropion pregnancy

Pingback: ashwagandha side effects reddit

Pingback: celebrex withdrawal symptoms

Pingback: buspar alcohol

Pingback: augmentin for skin infection

Pingback: or ibuprofen for arthritis

Pingback: remeron and alcohol

Pingback: dibose acarbose

Pingback: abilify lawsuit 2022

Pingback: does robaxin have aspirin in it

Pingback: actos-leipzig.de

Pingback: repaglinide uv absorbance

Pingback: semaglutide yerba mate

Pingback: protonix vs.omeprazole

Pingback: ivermectin coronavirus

Pingback: venlafaxine contraindications

Pingback: what is shelf life of voltaren gel

Pingback: spironolactone hyperkalemia

Pingback: sitagliptin 100 metformin 850

Pingback: levaquin synthroid

Pingback: tamsulosin time to work

Pingback: tizanidine 4mg used for

Pingback: cialis online pills

Pingback: viagra cialis levitra online

Pingback: voguel sildenafil 100mg

Pingback: mint pharmaceuticals tadalafil reviews

Pingback: sildenafil para que sirve en mujeres

Pingback: rx pharmacy charlotte nc

Pingback: how to make levitra more effective

Pingback: trazodone price pharmacy

Pingback: vardenafil generico precio

Pingback: ivermectin uk buy

Pingback: buy ivermectin cream for humans

Pingback: tadalafil 40

Pingback: stromectol tab price

Pingback: tadalafil and vardenafil

Pingback: 100mg sildenafil for sale

Pingback: vardenafil trihydrate hydrochloride

Pingback: how to get sildenafil prescription

Pingback: ivermectin australia

Pingback: ivermectin nz

Pingback: order stromectol online

Pingback: what is cephalexin used for in dogs

Pingback: can you drink alcohol while taking prednisone

Pingback: doxycycline dosage for std

Pingback: how fast does valacyclovir work

Pingback: ciprofloxacin 500mg used for

Pingback: amoxicillin for strep throat

Pingback: contraindications for trimox

Pingback: maximum dose of pregabalin for pain

Pingback: provigil slate

Pingback: trazodone names

Pingback: lisinopril dosage 10 mg

Pingback: what is the benefit of taking metformin at night

Pingback: keflex 500 mg capsule

Pingback: how long does nolvadex take to get rid of gyno

Pingback: how long does tadalafil 10mg last

Pingback: medstore online pharmacy

Pingback: buy viagra online cheap

Pingback: vardenafil costco

Pingback: levitra half life

Pingback: how should i take sildenafil for best results

Pingback: sertraline and sildenafil together reddit

Pingback: is sildenafil over the counter

Pingback: sildenafil coupons

Pingback: can you drink alcohol with sildenafil

Pingback: pharmacy online 365 reviews

Pingback: what is better sildenafil or tadalafil

Pingback: cialis viagra levitra

Pingback: does cialis make you last longer in bed reddit

Pingback: is levitra better than viagra

Pingback: levitra 60 mg price

Pingback: sublingual vardenafil

Pingback: clozapine registered pharmacy

Pingback: sildenafil for premature ejaculation reviews

Pingback: what to consider as budget when running pharmacy store

Pingback: cialis dosage 20mg

Pingback: tadalafil when to take

Pingback: atlantic pharmacy viagra

Pingback: tadalafil 5mg reviews

Pingback: retail pharmacy price cialis

Pingback: tadalafil dosage

Pingback: sulfasalazine and melatonin

Pingback: how often can you alternate tylenol and motrin for a toddler

Pingback: para que sirven las celecoxib

Pingback: celebrex en español

Pingback: indomethacin and necrotizing enterocolitis

Pingback: what is diclofenac used for

Pingback: can i purchase generic pyridostigmine without a prescription

Pingback: lioresal sucht

Pingback: dosis de meloxicam en ratas

Pingback: imuran and sun

Pingback: is maxalt otc

Pingback: drug interactions with imdur

Pingback: para que sirve sumatriptan succinate

Pingback: who makes piroxicam

Pingback: mobic weight gain

Pingback: can you take rizatriptan and paracetamol

Pingback: periactin pediatric dose

Pingback: brookwood avenue artane dublin

Pingback: cyproheptadine pediatric dosing

Pingback: can you buy generic ketorolac

Pingback: zanaflex kidney disease

Pingback: can i order generic toradol without prescription

Pingback: how to get high on tizanidine