.png)

.png)

.png)

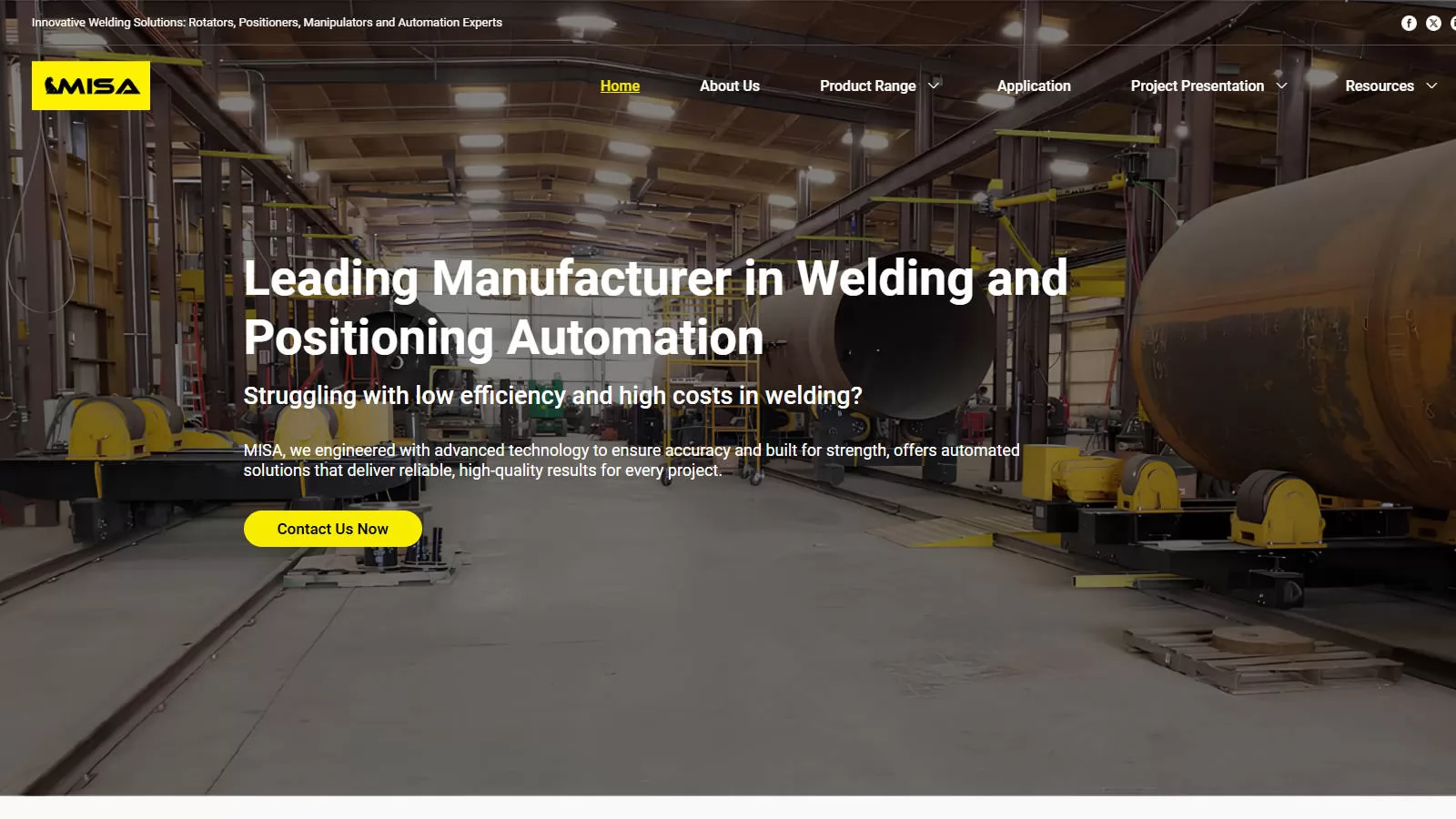

Company Overview: MISA is a leading global manufacturer specializing in high-quality welding, positioning automation equipment. Founded with a vision to drive innovation and reliability in industrial manufacturing, we have built a reputation for delivering products that meet the rigorous demands of industries worldwide.

At MISA, we have an organized and efficient structure that allows us to deliver the highest standards in quality, innovation, and customer satisfaction. Our team is composed of dedicated professionals across various departments, each playing a vital role in our mission to deliver world-class equipment solutions.

All the employee work for MISA will do their best to supply customer best quality machine and service!

Founded: Over 10 years of experience in welding automation

Products:

Application Areas:

Customer Reviews:

Company Overview: Since 2002, WuXi Fengwei Mechanical Equipment Co., Ltd has devoted to research & development and manufacturing of automatic machinery products in 6,000m² closed areas. Until now, we grow into a 40,000m² production base with the adopted principle of producing high quality and latest technology, continue its service with ISO 9001 quality system and produce CE certified machines.

Founded: Established in 2002 with over 20 years of industry experience

Products:

Application Areas:

Customer Reviews:

Company Overview: SENLISWELD is China’s leading welding automation and CNC cutting machine company for over two decades. We have manufactured the most reliable welding machines for both our local and international clients.

Along with the skills and experience, we have the trust of our loyal customers in 40 countries across all 7 continents. We put customers’ satisfaction at the forefront of our company’s vision and mission.

Since 1999. SENLSIWELD has excelled in manufacturing all varieties of the most widely used welding automation machines for a diverse range of industries.

SENLISWELD is the ONE-STOP-SHOP to upgrade your business’s welding operations. We are not merely suppliers but also your business partners.

Founded: Founded 1999 Over 20 Years Experience

Products:

Application Areas:

Customer Reviews:

Company Overview: Ji'nan North Machinery Co., Ltd. is a Sino foreign joint venture company, foreign personnel in enterprises. Professional products and technology of Ji'nan North Machinery Co., Ltd. since its establishment, to introduce and absorb the international advanced level, professional engaged in a variety ofpositioner, positioner, welding positioner, light roller frame, DC motor and welding, cutting and auxiliary equipment R & D, production, sales and technical services.

Ji'nan North Machinery Co., the company always uphold the "sincere plain" faith, the long-term cooperation with universities and research institutes, is committed to building a high-quality personnel and product system.

The company mainly produces welding positioner, welding positioner, welding, welding turntableturntable, turning platform, light roller frame, all kinds of wire feeder series products. The companyperennial products exported to Europe, Australia, Southeast Asia and other countries, won the trust of customers at home and abroad.

Founded: Early 2000s

Products:

Application Areas:

Customer Reviews:

Company Overview: Wuxi LEMAR Machinery Equipments Co., Ltd. is located on the shore of Taihu Lake in Wuxi, more than 100 kilometers away from Shanghai, close to the Beijing-Shanghai high-speed railway, with a beautiful environment and convenient transportation.

LEMAR Machinery is a high-tech enterprise integrating R&D, production and sales. For many years, it has been committed to automatic welding and cutting equipment and H-beam production line equipment. We have complete welding and cutting equipment and a high degree of mechanical automation, which greatly improves the production efficiency of customers. Most of the products have passed China National CCC certification and ISO9001 international quality system certification.

The products sell well in more than 20 provinces and cities across the country, and are exported to more than 30 countries,UK,USA,Southeast Asia, India,the Middle East, Europe and the United States.

Founded: Over 20 years of industry experience

Products:

Application Areas:

Customer Reviews:

Company Overview: Wuxi OLIVET Machinery Equipment Co., Ltd lied Huishan Economic development zone, Wuxi, China Necessary complete, transportation convenient, only 180km away from Shanghai Pudong Airport, Shanghai Port, and can be arrived at by way of highway.

Our company which gather research and development, manufacture and sale, majoring in the line of automatic welding equipment such as adjustable welding rotator and welding chuck, cutting equipment, milling equipment, environmental protection equipment. For many years service in the boiler, pressure vessel, petrochemical, electrical installation, metallurgy and steel other manufacturing industries. Products varieties, specifications, complete sets, supporting strong advantages, can complete configuration, single purchase, and can bemanufactured according to user requirements. The Company will be experienced manufacturing experience, the perfect design, meticulous work of the spirit, the integrity of service waiting for your patronage.

Founded: 2015

Products:

Application Areas:

Customer Reviews:

Company Overview: Established in 1999 and with a registered capital of $ 1.4 million, Wuxi ABK Machinery Co., Ltd a leading professional manufacturer of welding equipment, CNC cutting machines and tank jacking system in China, we mainly provide our customers with wind tower production line, H beam welding line, various welding equipment, pipe welding equipment, CNC cutting machine, tank jacking system and portable waterjet cutting machines.

And our products can be widely used in various fields, such as pressure vessel production, tank, petrol, chemistry, power, irrigation, traffic, ship building, aviation, heavy machinery, construction, and so on.

Founded: 1999

Products:

Application Areas:

Customer Reviews:

Co., Ltd_1744794872_WNo_1600d900.webp)

Company Overview: As a specialist in welding and cutting automation solutions, DIG is committed to helping heavy fabrication industries, such as shipbuilding, transportation, aerospace, energy, construction machinery, and rail transit industries to raise the level of productivity. In the demanding world of industrial operations, every efficiency gained and every second saved can translate to increased productivity and profitability. From our flagship model to our more compact versions, DIG ensures every industry need is catered for. Tailored solutions, unmatched results. DIG will be your trusted partner throughout the entirety of your project.

Founded: 2010

Products:

Application Areas:

Customer Reviews:

Company Overview: Luoyang Bota Heavy Industry Machinery Equipment Co., Ltd. is a manufacturer of various welding equipment and CNC cutting equipment with well-equipped testing facilities and strong technical force. Our company integrates research, development, manufacturer and sale.

With a wide range, good quality, reasonable prices and stylish designs, our main products include welding manipulators, rotators, positioners, CNC cutting machines, surfacing welding machines, pipe welding machines, tanks and wind tower production lines, etc. Our products are extensively used in petrochemical, pipeline, pressure vessel, heavy engineering and steel structure.

Our company adheres to "High Quality, High Level Service, Customer Demand-oriented" company philosophy. For several years, our products have been widely recognized and trusted by users and can meet continuously changing economic and social needs.

We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Founded: Operating for over 10 years

Products:

Application Areas:

Customer Reviews:

“Strong weld build and precise rotation under heavy loads.”

“Professional advice throughout the procurement process.”

“Stable performance over extended operation periods.”

Company Overview: Shijiazhuang Everlight Trade Co.,Ltd. Welding Consumable Dept., which is joined in from Hebei Machinery Import and Export Co.,Ltd. Export No.6 Deptment.

Shijiazhuang Everlight Trade Co.,Ltd. Established in 2005' and obtained the approval of ISO9001/Edition 2015 Quality System.

Everlight Welding Consumable Dept. has maintained long-term and regular business relationships with customers across Europe, Middle East, South American, Korea market etc.

Everlight Welding Consumable Dept. export Welding Machinery, Welding Consumable and Welding Component for more than 18 years. The products including Welding Electrodes Production Line, Welding Machine, Plasma Welding Machine, Cutting Machine, Welding Torch, Cutting Torch, Welding Wire, Welding Electrodes, and relative Welding products. It is our great honor to satisfy your requirements on welding products. Any requirement from you will be maximized by us.

Founded: 2005

Products:

Application Areas:

Customer Reviews:

Definition and Purpose

A welding positioner is an essential tool used in manufacturing and industrial welding. Its main function is to rotate or tilt workpieces into the most ergonomic and efficient position for welding. This helps ensure consistency, safety, and precision in the welding process. Think of it as the third hand of a welder—stable, reliable, and critical for handling complex or heavy components.

Key Components and Mechanism

Welding positioners typically feature a rotating table or platform, motorized or manual tilting mechanisms, and control panels. Some models come equipped with programmable systems for repetitive tasks. The frame, chuck, and motor must work in sync to accommodate various sizes and weights of parts while maintaining balance and alignment.

Increased Efficiency

By eliminating manual repositioning, welding positioners streamline production, saving valuable time. Welders can focus on their task without interruption, reducing cycle time significantly.

Enhanced Safety

Handling heavy and awkwardly shaped materials is a major hazard in welding. Positioners remove this risk by automating movement and keeping welders out of danger zones.

Improved Precision

Proper positioning allows for better control of welding angles and speeds, ensuring cleaner and more consistent welds. This minimizes rework and boosts overall quality.

Rotary Welding Positioners

These are the most common and are ideal for circumferential welding. The workpiece is mounted on a rotating table that spins at a controlled speed.

Head and Tailstock Positioners

Best for long and heavy components, these machines hold the workpiece at both ends, offering precise rotation along its center axis.

Tilt and Turn Tables

These allow the workpiece to be both tilted and rotated, offering maximum flexibility for multi-angle welds. They're perfect for intricate components and odd shapes.

Automation and Smart Technologies

With Industry 4.0 leading the charge, welding positioners now feature automation, touch-screen interfaces, and programmable logic controllers (PLCs) for advanced control.

Customization Demands

Clients increasingly require tailored solutions—custom jigs, fixturing setups, and special movement parameters—to match their unique production needs.

Integration with Robotic Arms

To boost productivity, welding positioners are often integrated with robotic arms, enabling seamless coordination for automated welding systems.

Historical Growth

China's industrial boom in the past two decades has fueled massive growth in equipment manufacturing. Welding positioners, in particular, saw increased demand in sectors like shipbuilding, pressure vessels, and automotive.

Export Impact

Chinese manufacturers now export welding positioners globally, offering quality equipment at competitive prices. This has reshaped the global sourcing landscape.

Competitive Pricing and Innovation

Combining affordability with innovation, many Chinese companies offer ISO-certified products with advanced features rivaling Western brands.

How to Vet a Manufacturer

Questions to Ask

Factory Visit Tips

Q1: What certifications should I look for?

A: ISO9001 and CE are standard. Look for SGS or BV for added assurance.

Q2: Are Chinese machines reliable?

A: Yes, especially from established manufacturers with global clients and R&D investments.

Q3: Can I get after-sales service internationally?

A: Many top manufacturers offer remote diagnostics and overseas support networks.

Q4: How long does shipping take?

A: Standard sea shipping takes 20-40 days. Air freight is quicker but costlier.

Q5: What is the typical warranty?

A: One year is common, but some offer extended warranties up to three years.

Q6: How do I get customization?

A: Provide detailed specs or CAD drawings. Most Chinese suppliers offer OEM/ODM services.

Welding positioners are critical to improving safety, speed, and weld quality. Chinese manufacturers like MISA MFG and others have not only caught up with global standards but are now setting new benchmarks in automation, customization, and cost-effectiveness. Whether you're a small workshop or a large fabrication plant, sourcing from China offers a smart balance of quality and affordability.