.png)

.png)

.png)

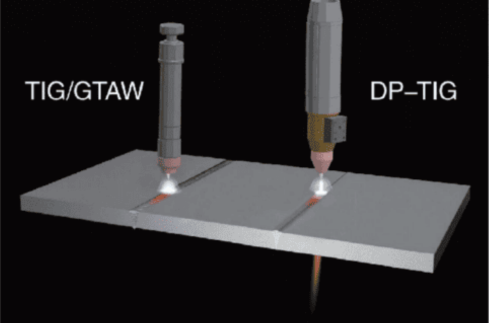

Deep penetration tungsten inert gas weld- ing(DP-TIG) is a new and efficient automatic welding process, which adopts a new welding method that can achieve"Keyhole" ( key- hole or small hole), combined with a special high-power welding torch, it solves the problems of traditional TIG arc stiffness, shallow penetration, and low welding efficiency.

DP-TIG achieves the effect of plasma arc through efficient electromagnetic compression of the arc. The arc energy is concentrated during welding. During the welding process, the arc pressure and the surface tension of the liquid metal in the molten pool are balanced to form a stable small hole ( keyhole) effect.

Super penetration ability, can penetrate 304 stainless steel plates below 14mm and titanium alloy plates below 16mm at one time. It is a brand-new welding process between traditional argon arc welding and plasma welding. It not only has the beautiful covering effect of traditional argon arc welding, but also has the excellent penetration power of plasma welding.

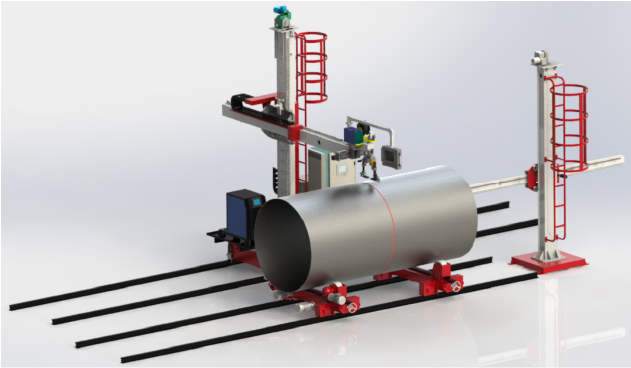

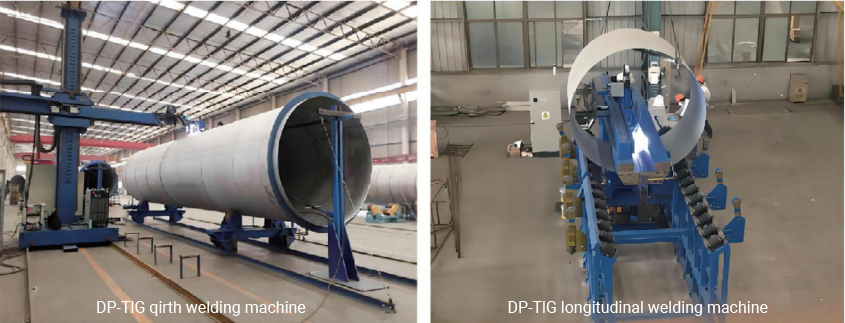

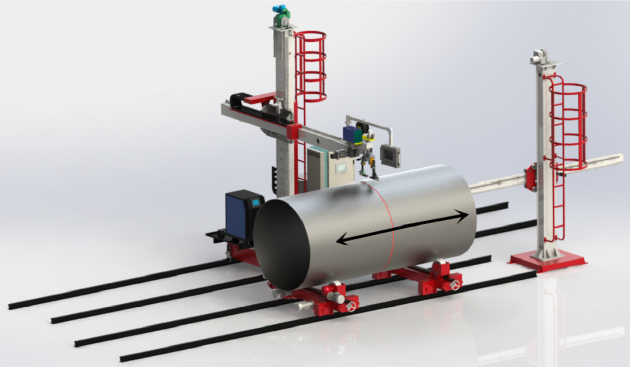

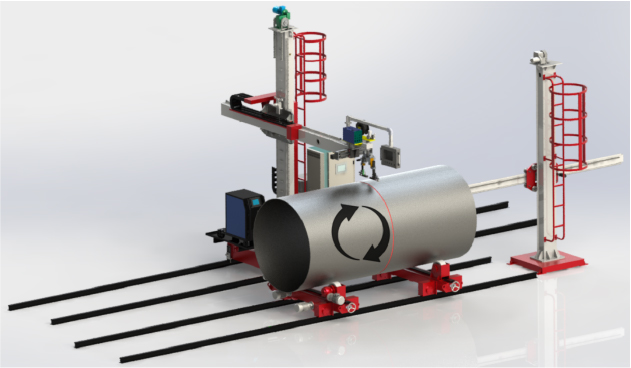

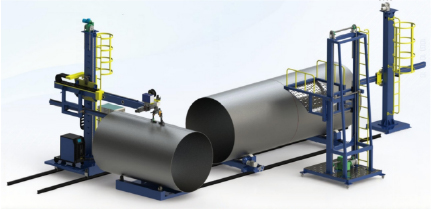

Longitudinal seam welding: The workpiece is placed on a roller frame, and the welding head is installed on a dedicated high-precision operating frame crossbeam slide support. The crossbeam slide is moved to adjust the welding position, and the workpiece is moved in a straight line by the roller frame (driven by a servo motor or AC with Inverter). The back air protection cross is fixed to the welding torch, and the back air protection is used to form the weld seam, completing longitudinal seam welding and single-sided welding double-sided forming.

Longitudinal seam welding: The workpiece is placed on a roller frame, and the welding head is installed on a dedicated high-precision operating frame crossbeam slide support. The crossbeam slide is moved to adjust the welding position, and the workpiece is moved in a straight line by the roller frame (driven by a servo motor or AC with Inverter). The back air protection cross is fixed to the welding torch, and the back air protection is used to form the weld seam, completing longitudinal seam welding and single-sided welding double-sided forming.

The arc energy is high, the stiffness is high, the weld penetration is large, and the penetration power is excellent. Medium and thick plates made of carbon steel, stainless steel, titanium alloy and other materials can be pen- etrated at one time, and the back is formed well;

Fast welding speed, can reach more than 3-8 times the traditional arc welding;

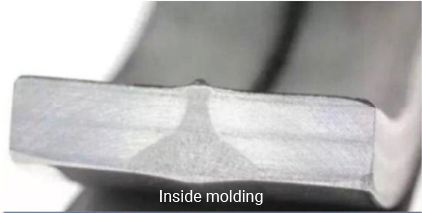

Fully melting method, compressing arc, using keyhole effect can achieve single-sided welding double-sided molding, with smooth and beautiful welds and small deformation;

Compared with the plasma welding technology, there is no plasma gas control, the arc collection control is easier, and the welding is more reliable;

The arc has good control ability and regulate ability;

The bottom welding group has a low requirements for the gap and the error border, and the tolerance of the wrong border clearance of the workpiece is large;

The pores are low sensitivity, avoiding welding defects such as pores.

Reduce the amount of multi-layer and multi - welding pollution, as well as the amount of consumables such as welding wires, protective gas, etc., saving comprehensive costs;

The workpiece does not need to milling the bevel, shortening the preparation time before welding, and the advantages of welding thickness are obvious

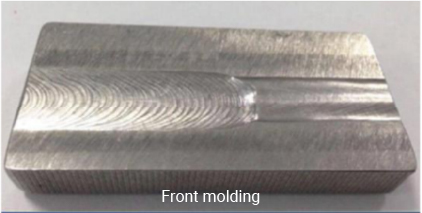

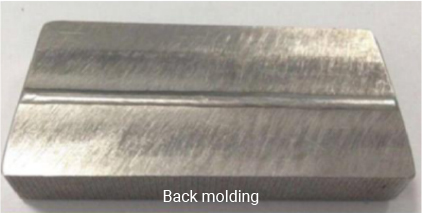

Stainless steel 14mm does not milling the bevel welding

Titanium 16mm does not milling the bevel welding

DP-TIG welding machine( Arc pressure tracking system + welding power supply + refrigeration water tank + control system); Special welding gun with high power;

power cords, ground wires, argon gauge;

Automatic wire delivery machine, welded automatic tracking system, automatic welding equipment, welding imaging system

Parameters of the welding technology of austenite stainless steel and its nickel-based alloy:

|

Material Thickness (mm) |

Welding Current (A) |

Welding Speed (mm/min) |

Welding Allowed Gap (mm) |

|

3 mm |

270 |

500 |

0.5 |

|

4 mm |

325 |

350 |

0.5 |

|

6 mm |

425 |

300 |

0.8 |

|

8 mm |

480 |

280 |

1.0 |

|

10 mm |

500 |

240 |

1.5 |

|

12 mm |

520 |

220 |

1.5 |

Parameters of the welding technology of austenite stainless steel and its nickel-based alloy:

|

Material Thickness (mm) |

Welding Current (A) |

Welding Speed (mm/min) |

Welding Allowed Gap (mm) |

|

3 mm |

270 |

500 |

0.5 |

|

4 mm |

325 |

350 |

0.5 |

|

6 mm |

425 |

300 |

0.8 |

|

8 mm |

480 |

280 |

1.0 |

|

10 mm |

500 |

240 |

1.5 |

|

12 mm |

520 |

220 |

1.5 |

Parameters of the welding technology of austenite stainless steel and its nickel-based alloy:

|

Material Thickness (mm) |

Welding Current (A) |

Welding Speed (mm/min) |

Welding Allowed Gap (mm) |

|

3 mm |

270 |

500 |

0.5 |

|

4 mm |

325 |

350 |

0.5 |

|

6 mm |

425 |

300 |

0.8 |

|

8 mm |

480 |

280 |

1.0 |

|

10 mm |

500 |

240 |

1.5 |

|

12 mm |

520 |

220 |

1.5 |

Parameters of the welding technology of austenite stainless steel and its nickel-based alloy:

Tungsten pole: 6mm tungsten pole;

Before welding, the surface oxidation layer and oil pollution on the front and back of the welding area should be removed;

Protecting gas: pure pheasant, flow of 20L/ min;

The gap between the product is less than the allowable gaps listed in the table;

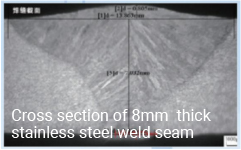

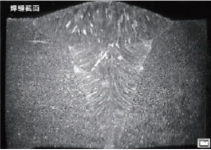

Welding quality comparison -- High-quality, high-efficiency welding

|

Welding technology |

Welding method |

Form after welding |

Summary comparison |

|

TIG/GMAW Traditional welding |

|

1.Multi-layer and multi-channel filling welding, prone to slag, pores and other phenomena; 2.Welding variable is large; 3.High requirements for operating workers' skills and responsibility; 4.The one-time qualification rate of weld filming is less than 90%; |

|

|

DEEP-TIG deep penetration key- hole TIG welding |

|

1. One-time welding success, no pores, slag clamping and other phenomena; 2. Double-sided molding, welding seams are smooth and beautiful, welding variable is small; 3."Nail"-like section structure, enhance the performance of welding seams; 4.The one-time qualification rate of welding seams exceeds 95%; |

|

Note: The above summary of the actual welding parameters of 10mm stainless steel.

Welding efficiency comparison -- Efficiency is more than 8 times

|

Welding technical process |

Preliminary processing material |

Cutting the bevel |

Clean before welding |

Fit-up |

Welding front |

Reverse clearing |

Welding back |

Number of welding times |

|

TIG/GMAW Traditional welding |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

Multi-number |

|

DEEP-TIG Penetration welding |

✔ |

× |

✔ |

✔ |

✔ |

× |

× |

One-time |

Welding efficiency comparison -- Efficiency is more than 8 times

Welding technology comparison -- Save materials:95%

|

Welding technology |

Splice form Form after welding Advantageous comparison

|

Summary comparison

|

|

TIG/GMAW Traditional Welding |

|

Large consumption welded material, at the same time wast- ing the bevel materials;

Welding material filling consumption reaches 1000g/m; |

|

DP-TIG deep penetration key- hole TIG welding |

The filling wire area of the covered side, the rest are self-molten areas |

Welding material consumption consumption is small or does not fill in welding material; The amount of welding material filling is not greater than 50g/m, which is 5% of the traditional TIG |

Note: The above summary of the actual welding parameters of 10mm stainless steel.

The Deep Penetration TIG Welding System refers to a specialized process that enhances the penetration depth of the weld compared to conventional TIG (Tungsten Inert Gas) welding. This process is particularly useful for applications requiring high-quality welds with minimal defects, deep fusion, and a clean weld bead.

Here are the key aspects of a Deep Penetration TIG Welding System:

Key Concept: The process is designed to achieve deeper weld penetration while retaining the precision and clean appearance associated with TIG welding. High-Power Density: It often uses high-energy density arc adjustments to achieve deeper fusion, sometimes involving modified power sources or pulse settings. Arc Concentration: Techniques like modifying the nozzle or adding magnetic control to focus the arc further enhance penetration.

Heavy-Duty Industries: Shipbuilding, pressure vessels, power generation, and chemical processing industries. Material Types: Stainless Steel Carbon Steel Titanium and Nickel Alloys Aluminum (special variants) Typical Uses: Welding thick components with fewer passes. Fabrication requiring high-quality welds with low porosity.

DP-TIG achieves the effect of plasma arc through efficient electromagnetic compression of the arc. The arc energy is concentrated during welding. During the welding process, the arc pressure and the surface tension of the liquid metal in the molten pool are balanced to form a stable small hole ( keyhole) effect.

Super penetration ability, can penetrate 304 stainless steel plates below 14mm and titanium alloy plates below 16mm at one time. It is a brand-new welding process between traditional argon arc welding and plasma welding. It not only has the beautiful covering effect of traditional argon arc welding, but also has the excellent penetration power of plasma welding.