.png)

.png)

.png)

What do you think the future of welding loos like? Do you believe that automation is key to competitive manufacturing? Or do you think that there’s actually more than automations, robotics, and welding systems?

In this blog post, we will give you a sneak peek of the welding industry’s future. When I say future, I mean how the next few years would look like for the industry, given that all machines and equipment are being used and leveraged.

Key Points:

https://youtu.be/lhSMM9CtpGs?si=oCNsIJH20vFhvAC6

There are a lot of mixed definitions and misconceptions about what welding automation is. But, all it is, is the process that assist welding tasks through the use of automation. These can be automation through advanced machines, specialized equipment, programs and software.

To give you an idea of what automated welding looks like, imagine computer programs, robotic arms, welding sensors, and other levers being the ones used for welding. The welder, you ask? They’re just observing and regulating the entire operation at safe distances.

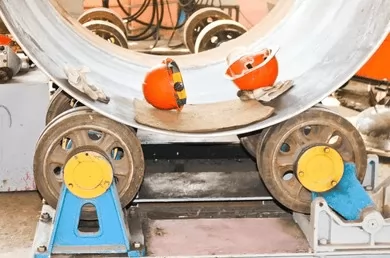

Today, you’ll find many classifications and types of automatic welding equipment, like our self-aligning welding rotator. This machine can accept and work on any cylindrical workpiece, aligning itself to meet the specific ranges.

Add our LH series fixed and manual welding column and boom with cross side and seam tracker for flange welding to that and you got yourself a reliable semi-automatic welding system.

There are literally tons of options to choose from and you’ll never experience a shortage of the exact models you want!

You might be wondering why there’s a sudden spring in the relevance of welding automation not just in the manufacturing sector, but in other industries as well.

The short answer to that is because we are already living in the digital age. The long answer – because it offers many advantages, benefits, and convenience to businesses and their people. Below we’ll list a few reasons why they take a high place in the operations of businesses and corporations.

Check this video out to see how automated welding improves health!

https://youtu.be/TTdHxswp_GA?si=I4tfYN71N5nn7x2C

Welding automation has been an immaculate addition to the world of manufacturing. They’re practically the definition of efficiency if you’ve been able to make the right investment.

The world of manufacturing is a never-ending loop of development and progress. However, automated welding placed a big fat green check on the industry especially in certain areas. With the competitive world of manufacturing, there are many different advantages automation has, these include:

Let’s talk output. First and foremost, this is the main thing businesses want when it comes to them investing. How would their output look? Will it be efficient? Can they save money and/or time?

Businesses that depend on high-quality welds must use automated welding systems. Why? – Because they offer a consistency that human welding just cannot match.

The overall quality of manual welding can be compromised by variables like as the welder's experience, weariness, or plain human mistake, which can cause results to vary. Automated systems, on the other hand, can precisely duplicate the same weld each time, doing away with inconsistent results.

Another thing is that automated welding offers a higher level of productivity. For the most part, welding automation increases efficiency dramatically and provides firms with many important benefits.

Unlike hand welders who need rest times, automated systems execute continuous welds without the need for breaks, streamlining operations. The productivity and speed of manufacturing are increased by this continuous workflow.

Automation also lessens human error, guaranteeing consistent, high-quality welds with no need for repair. This lowers material loss and downtime brought on by error correction.

Of course, not having to worry about labor shortage is one of the best things when running a man-powered businesses. By using less human work, firms and corporations can drastically decrease labor costs using automated welding processes.

Automated systems are meant to do repetitive welding activities fast and accurately, in contrast to manual welding, which is labor- and time-intensive. Due to increased efficiency, fewer people are required to meet the same production targets, which enables businesses to reduce labor costs.

Furthermore, automation reduces errors that usually arise from manual labor, which reduces the need for reworks and waste and ultimately improves operational efficiency. This results in cost reductions and an overall increase in profitability for organizations.

Last but most definitely not least would be the innovations they offer in the future. You see, automating welding processes and systems don’t just end there – it’s only the beginning.

The future of welding automation is brimming with exciting innovations that promise to enhance efficiency, precision, and productivity. One of the key advancements is the rise of collaborative robots, or cobots, which work side-by-side with human welders.

Cobots take on repetitive tasks, allowing welders to concentrate on more intricate work, boosting overall productivity. nexAir's KnowHow™ expertise in integrating these robots into workflows has already transformed welding operations for many businesses.

Machine learning and artificial intelligence are two more noteworthy advances. Welding settings can be changed in real time by AI-driven welding systems, guaranteeing excellent weld quality. These systems perform better as they learn and develop, easily adjusting to different materials and environments.

From the glitz and glamour or high-tech automatic welding equipment to the safety and security of your projects, MISA welding is here to provide everything you need! We’ve honed our competence in automatic welding positioners, CNC cutters, and H-beam production lines over years of experience.

What sets us apart is our dedication to precision and service. With a professional design team offering fully customized solutions, our team can clearly oversee production lines with stringent quality control processes.

Whether you’re looking for advanced and high-tech welding equipment or expert consultation, you can count on us! Reach out to us and get a free estimate!