.png)

.png)

.png)

In the world of fabrication, achieving efficiency, quality, and safety in welding operations is paramount. Positioners, specifically designed for welding, play a crucial role in reducing manual labor, enhancing weld quality, and boosting production speed. By ensuring optimal positioning of weldments, MISA’s positioners enable welders to work in the most ergonomic and productive orientations, especially useful for high-volume shops where consistent output and quality are essential.

For businesses striving to improve their welding processes, a positioner is a wise investment. Here’s how MISA’s advanced positioners brought convenience, precision, and safety to our customers, illustrated through a real-world example with our valued customer from Thailand.

Welding in a flat, controlled position yields significant advantages:

Positioners provide these benefits by reducing the physical demands on operators, creating an environment where precision and control come naturally.

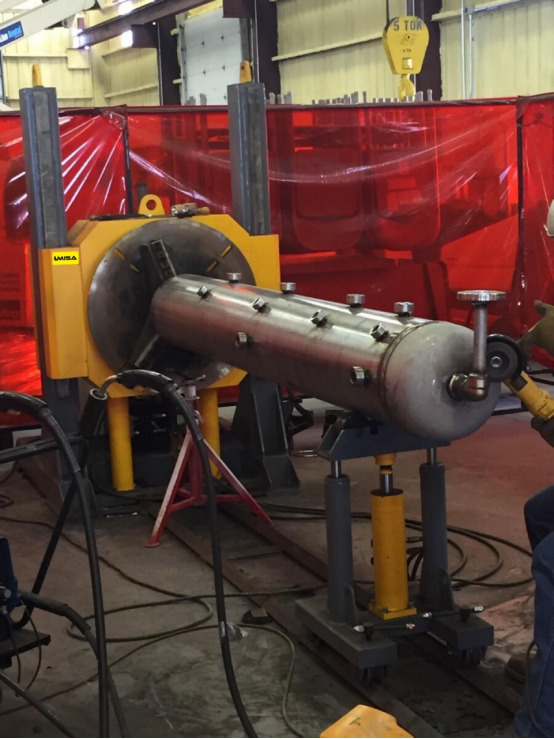

Our customer from Thailand, a large-scale manufacturer specializing in slender pipe welding, required a solution that would enable efficient welding of long, tubular workpieces. The traditional setup posed difficulties in ensuring proper alignment and support, often resulting in uneven welds and reduced efficiency.

Understanding these challenges, MISA’s team recommended a head-tail stock positioner uniquely configured to meet the customer’s specific requirements. Our head-tail stock weld positioners, ideal for elongated parts that require end-to-end support, offered a practical solution. For this client, welding slender pipes called for a setup that could hold the pipe firmly at both ends while allowing adjustable height and rotation control.

Equipment Highlights:

1. Head Stock Positioner with Hydraulic Lift: This advanced positioner provides a hydraulic lift function, allowing the operator to adjust the height for optimal ergonomic positioning. Coupled with a rotation mechanism, it enables the workpiece to be welded at any desired angle and height, facilitating a smoother workflow.

2. Adjustable Support Roller: To hold the tail end of the pipe securely, we introduced an adjustable support roller. This feature can be fine-tuned to align with the height of the head stock positioner, ensuring a stable and uniform setup for the entire length of the pipe.

3. Enhanced Control and Safety: The positioner minimizes the need for crane lifting and other potentially hazardous manual adjustments, creating a safer environment for operators.

This setup allowed the customer’s welders to work in a more comfortable, precise, and controlled environment, significantly improving weld quality and productivity.

Since implementing the head-tail stock positioner, our Thai customer has experienced several key improvements:

These benefits align with MISA’s commitment to creating customer-centered solutions that address specific operational needs, ensuring that each piece of equipment we provide offers true value and impact.

At MISA, our mission is to understand and solve the unique challenges our customers face. This case demonstrates our dedication to providing tailored solutions that bring tangible improvements to welding operations. Whether you’re dealing with cylindrical objects, elongated parts, or custom configurations, MISA’s range of positioners is designed to meet the highest standards of quality and efficiency.

By investing in a MISA positioner, businesses can enhance productivity, maintain superior quality, and create a safer, more ergonomic environment for their team. Ready to transform your welding operations? Connect with MISA today and experience the benefits of optimized positioning technology.