Who Is ArcelorMittal

We live in an age of rapid development, where inventions and human ingenuity are driving unprecedented progress in global development.

Technology plays a key role in this transition, but so do the materials from which our world is built. As the world’s leading steel and mining company, ArcelorMittal has an inherent stake and clear responsibility in this regard.

Steel is integral to the future success of our world. As one of the only fully reusable and recyclable materials, it will play a key role in building the circular economy of the future. Steel will continue to evolve, becoming smarter and more sustainable.

At ArcelorMittal, their aim is to help build a better world with smarter steel. Steel manufactured using innovative processes is more efficient, consumes less energy and has significantly lower carbon emissions. Cleaner, stronger and reusable steel. Steel for electric vehicles and renewable energy infrastructure to support the transformation of society in this century.

ArcelorMittal Is The Largest Steel Manufacturer In The Following Sectors:

- North America

- South America

- Europe

What They Did

With approximately 158,000 employees, ArcelorMittal is more than a company, it is a community. Driven by an entrepreneurial spirit and a passion for excellence, ArcelorMittal will continue to push boundaries. Whether developing technologies to reduce the carbon footprint of steel, transforming the built environment with new construction solutions, 3D printing automotive parts using steel powder, or by incorporating artificial intelligence and advanced automation in operations. This is what it takes to be the steel company of the future.

Led by ArcelorMittal’s global R&D team and supported by all aspects of their business, they are market leaders in innovation. They are constantly seeking technological advances that will enable the manufacture of new steels while improving the manufacturing process. This commitment to innovation extends beyond new products and processes to how they can positively impact the lives of people around the world. ArcelorMittal very focused on maximizing this impact by taking full advantage of the wide range of opportunities that today’s digital economy offers us.

Their Values

Since ArcelorMittal’s inception, the company’s goal has been to align all its activities with four values: Safety, Sustainability, Quality and Leadership.

Safety — success begins with ensuring the safety of all employees

Sustainability — wanting to be competitive and thrive in tomorrow’s world

Quality — Quality is critical to ArcelorMittal’s competitive advantage

Leadership — Establishing and maintaining our leadership position through visionary thinking and a willingness to continually challenge the status quo and a willingness to do things differently

Powering The World

Energy depends on steel. It provides the infrastructure that makes it possible to produce and transport a variety of energy sources, from solar and wind to oil, gas and nuclear. ArcelorMittal is the market leader in energy steels, producing specialty steels that meet the demanding operating conditions of this critical industry.

While the renewable energy revolution is underway, the world will remain dependent on traditional fossil fuels such as oil and natural gas during a transitional phase. ArcelorMittal supplies steel for onshore and offshore platforms, liquefied natural gas (LNG) vessels, pipelines, refineries and fuel storage. Steel plates are also central components in pressure vessels and many other major structural applications in power generation and petrochemical processing.

About Our Cooperation Between Companies—What MISA Can Do

MISA is an enterprise integrating R&D, manufacturing and sales. It is mainly engaged in the production of automatic welding equipment and fixtures, which can also be widely used in marine engineering, wind towers, pressure vessels, pipelines and steel structure industries.

When processing and manufacturing these pressure vessels, pipes, tanks and other equipment, MISA’s welding equipment plays a very important role. The production of these large storage tanks requires some auxiliary tools to facilitate welding.

We Solve Customers’ Production Problems

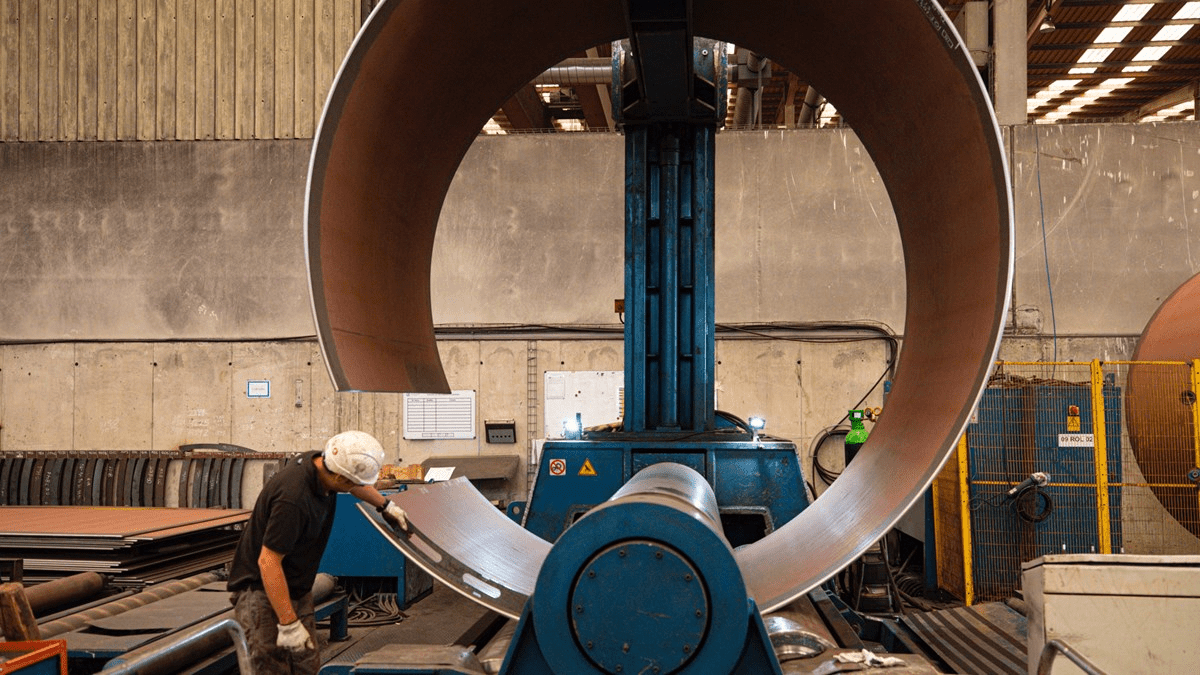

The welding process of heavy cylindrical workpieces is time-consuming and laborious, and the operation difficulty increases. Customers hope to use our welding equipment to reduce the difficulty of operation and carry out production smoothly. For the first cooperation, ArcelorMittal also gave us a lot of trust. After several weeks of program communication and on-site inspection of the factory, the customer first purchased 8 sets of welding rotators as a preliminary test. The welding rotator can support the cylinder workpiece within a certain diameter range, and the rotation of the roller is controlled by the hand control box or the foot switch. The friction between the roller and the cylinder drives the cylinder to rotate at a constant speed, which is convenient for the welder to weld the joint . And the welding rotator can move on the track, which makes it very easy to carry the heavy cylinder. After 35 days, 8 sets of welding rotators were completed according to the customer’s requirements. Since the equipment is delivered as a whole machine, the customer connects the power supply after receiving it and puts it into use immediately.

We increase productivity

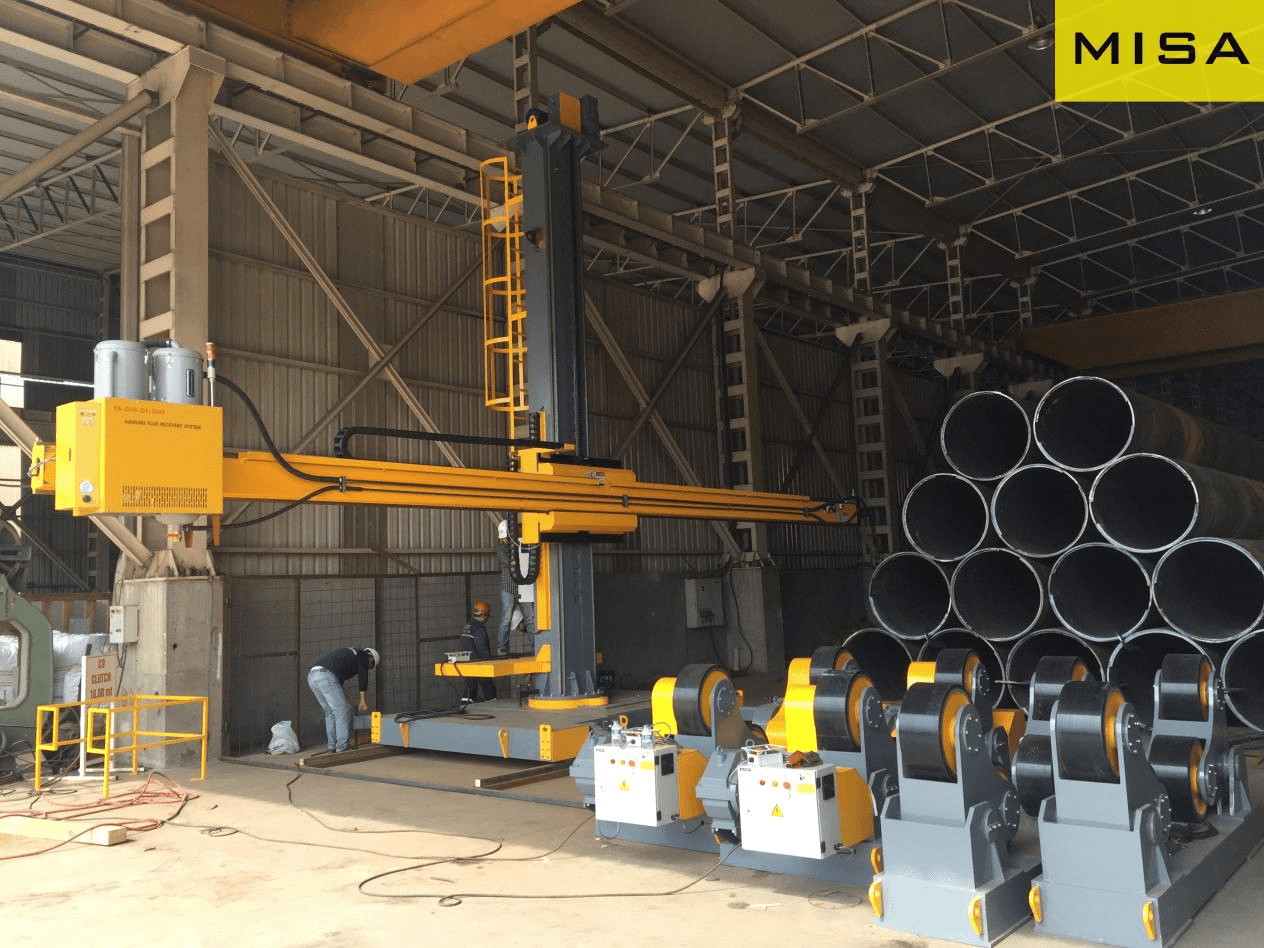

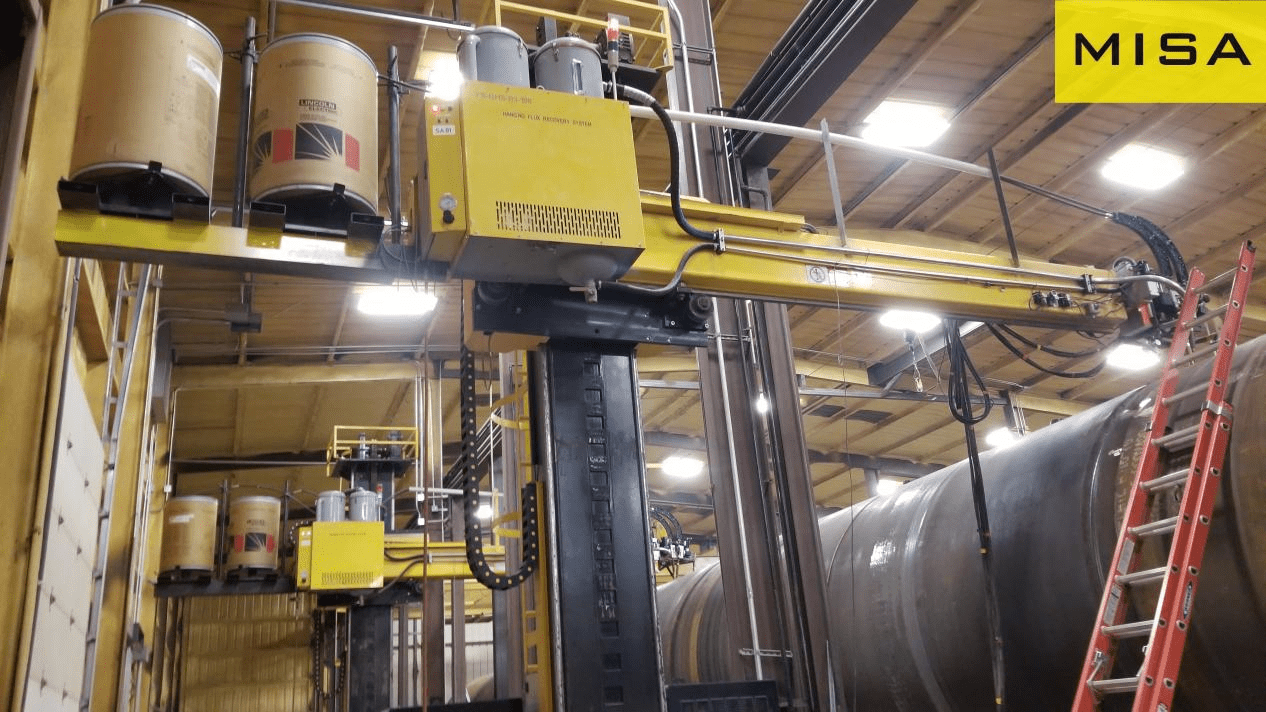

After two months of stable use, the customer is very satisfied with the performance of the equipment, and according to the company’s future production plan, consider purchasing an additional order of 5 sets welding manipulators and 16 sets of welding rotators.

Due to the large diameter of the large cylinder, the welder needs to use tools to achieve the required height of the weld during operation. After understanding the needs of customers, our sales and engineering team recommended purchasing welding manipulators and using it with welding rotators to form an automatic welding production line. Not only does this reduce the cost of manual operations, but automated machinery can also provide better precision. The welding manipulator is matched with Lincoln’s electric welding machine, which can not only weld the inner ring seam and outer ring seam of the cylinder, but also weld the inner longitudinal seam and the outer longitudinal seam. The production line composed of welding manipulator and welding rotator can ensure the safety of production and improve the production efficiency of the factory.

MISA Only To Bring Help To Every Customer

The most basic thing in manufacturing is manufacturing. MISA is down-to-earth and conscientious in making products, and strictly controls our production to ensure that every piece of equipment delivered to customers is qualified and perfect. Only with a good product as the foundation can we gain the trust of customers. Coupled with our quick response to customers’ questions and the perfect after-sales service system to deal with various problems in a timely manner, MISA has been firmly established in the industry for 15 years, serving many customers and making many friends. Customers who have cooperated with MISA have a repurchase rate of 85%. We attract customers with high-quality products and retain customers with high-quality services. Our products can bring production convenience to customers, solve production problems, and improve production efficiency, which is the purpose of MISA since its inception.