How To Choose A Welding Positioner

Welding positioner is a device used to hold and manipulate a workpiece during welding. It allows the welder to position the workpiece at the optimal angle for welding, improving the quality and efficiency of the weld. There are several types of welding positioners, each designed for specific applications:

- Rotary Positioners: Alao can called as Welding turning table or Welding turntable. These can rotate the workpiece around a horizontal axis, allowing for continuous welding without repositioning the workpiece manually.

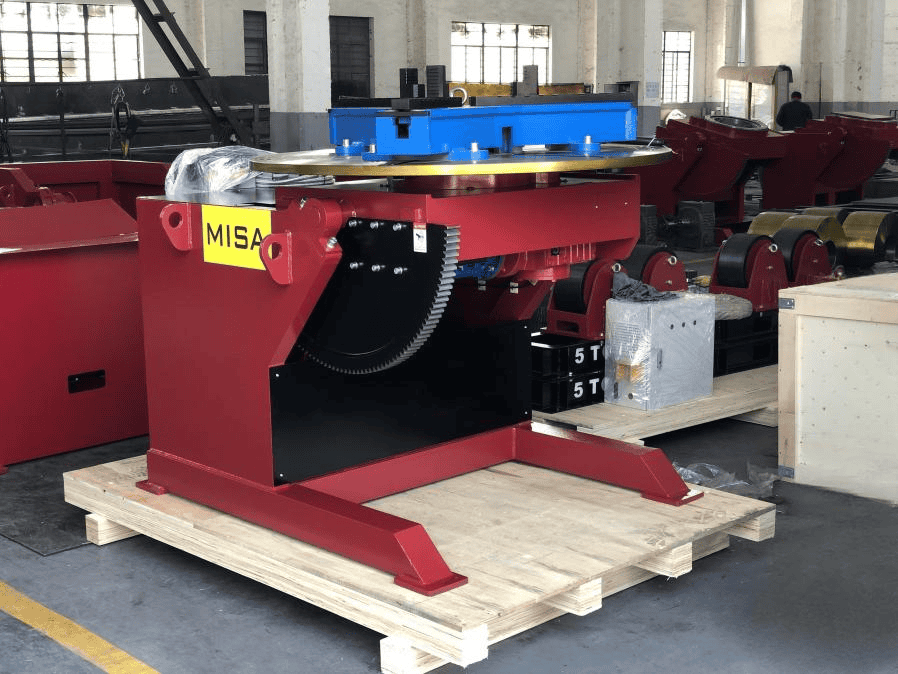

- Tilt and Turn Positioners: It’s a standard type Welding positioner. These positioners can tilt the workpiece to various angles and rotate it, providing access to difficult-to-reach areas.

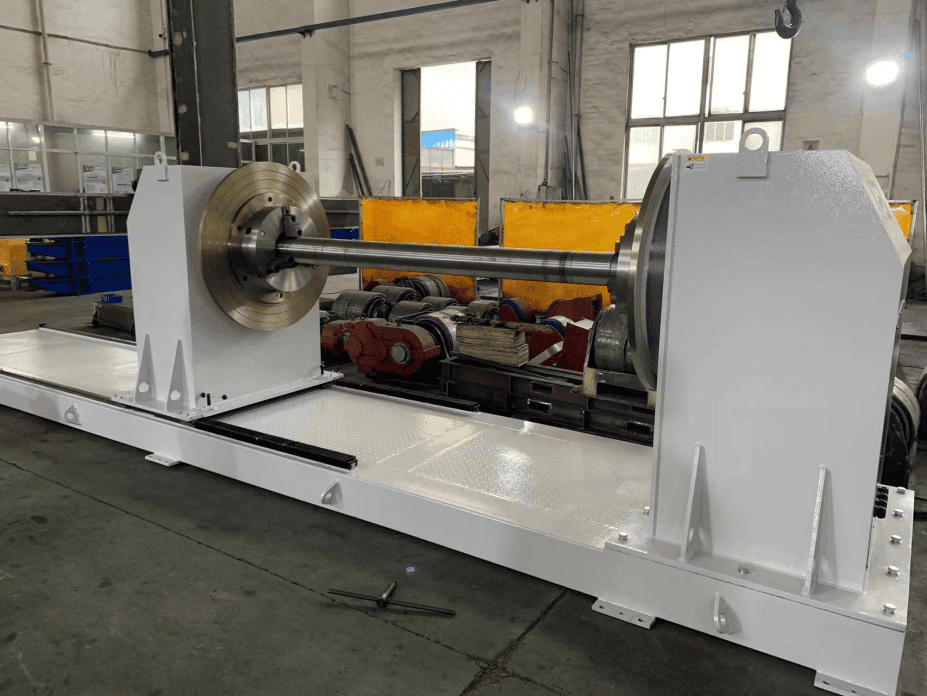

- Headstock and Tailstock Positioners: Used for larger workpieces, these positioners support the workpiece at both ends, allowing it to be rotated and positioned as needed.The workpiece height can be adjusted by raising and lowering to reach the required horizontal line.

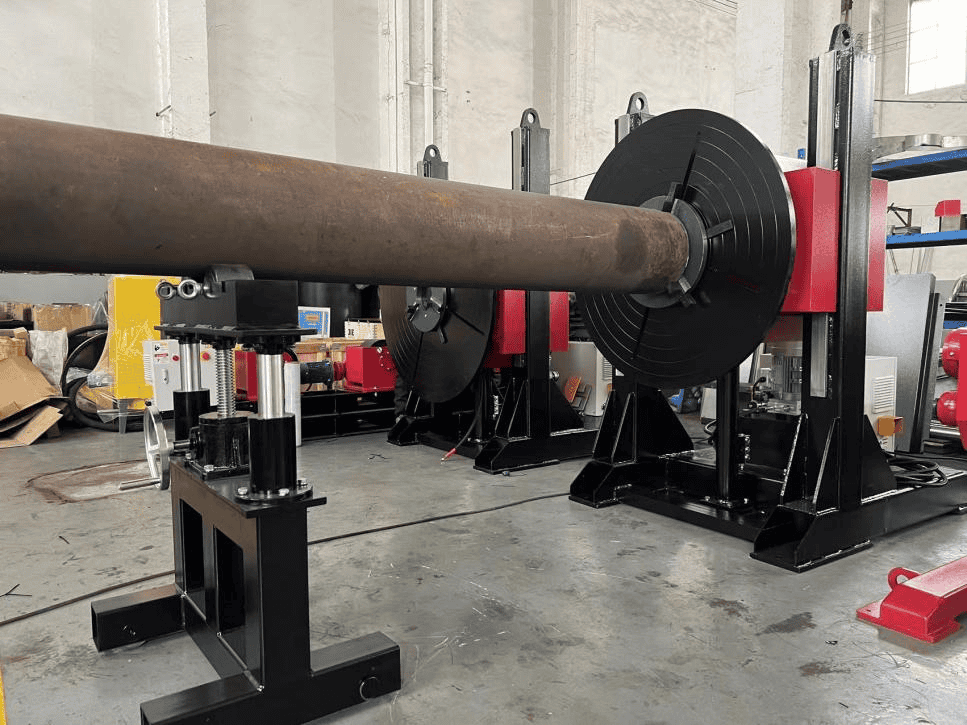

- Gripper Positioners: Designed to hold and rotate smaller workpieces, often used for pipe welding.Usually it is a headstock, The height can be adjusted by hydraulic lifting and the workpiece can be driven to rotate. The pipe can be fixed with a chuck on the countertop. If the pipe is longer, support roller is a good option.Hold the end of the pipe to balance it.

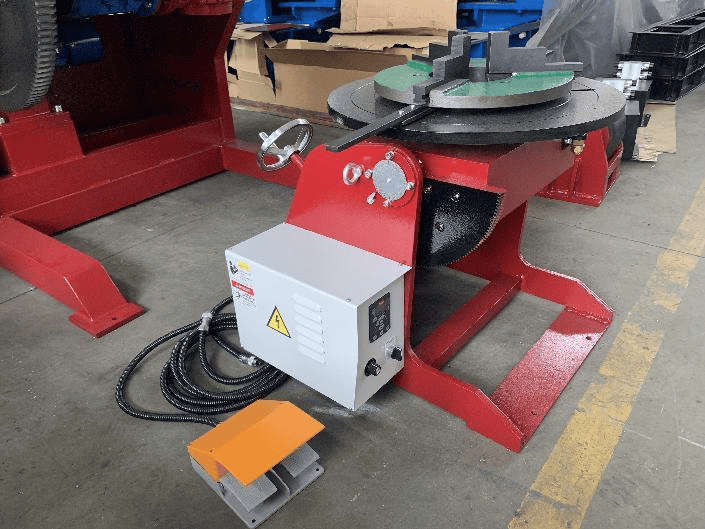

- Manual Positioners: Basic positioners that require manual adjustment, suitable for smaller or simpler tasks.Usually these are positioners with a load capacity of 100 kg and 300 kg. With motorized rotation and manual tilting.

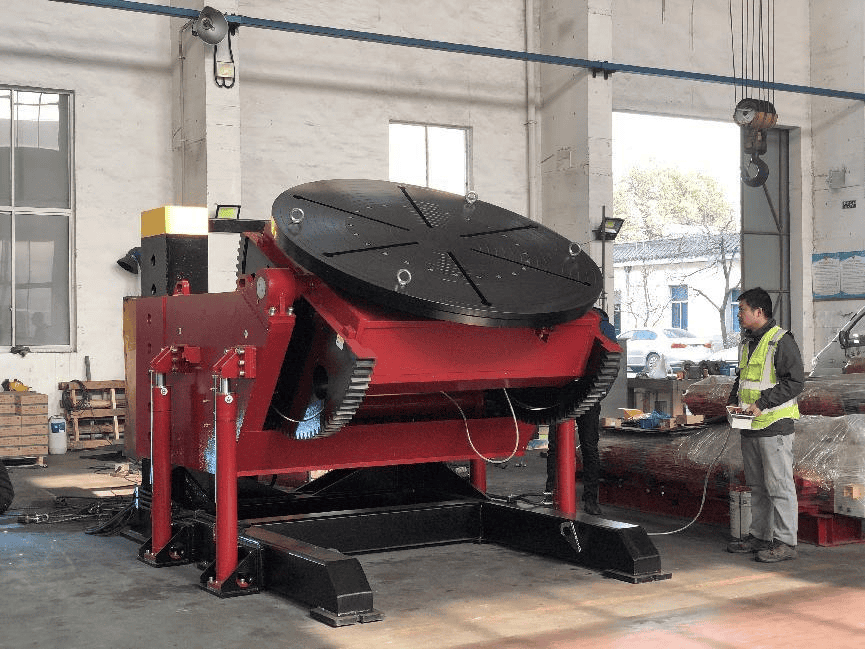

- ElevatingPositioners: The lifting and lowering of this type of positioner can be controlled manually or hydraulically. Hydraulic lifting is more powerful and stable. If the workpiece is large and heavy, hydraulic control is usually chosen.

- Hydraulic Positioner: The hydraulic positioner has three axis, hydraulic lifting, tilting and rotation. The height that the hydraulic lifting positioner table can reach is very high. The stroke of the oil cylinder is wide.

All Welidng Positioners equipped with motors and control systems to automatically adjust the position of the workpiece, often used in automated welding processes.

Using a welding positioner enhances safety by reducing the need for the welder to handle heavy workpieces manually, and it also ensures consistent weld quality by maintaining the correct position and angle throughout the welding process.