.png)

.png)

.png)

Buckets, primarily used in excavators, are critical for digging and moving loose materials. Their construction requires durability and resilience, as they often operate in harsh conditions. Manufacturing these buckets involves precise fabrication, robust welding processes, and specialized equipment to handle their size, weight, and irregular shape.

Buckets are typically categorized based on their applications and material strength requirements:

The bucket manufacturing process includes several stages:

Welding is a key aspect of bucket fabrication, as it affects both the strength of the weld joints and the overall durability of the bucket. The welding quality directly impacts the bucket’s tensile strength, bending performance, and resistance to failure under heavy loads.

Welding Process Factors:

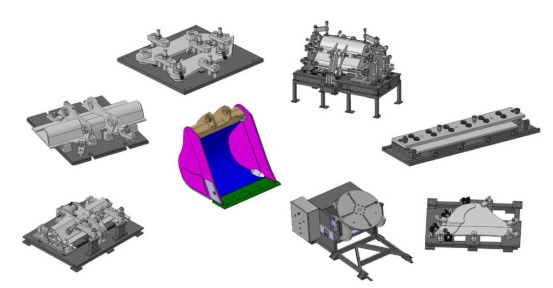

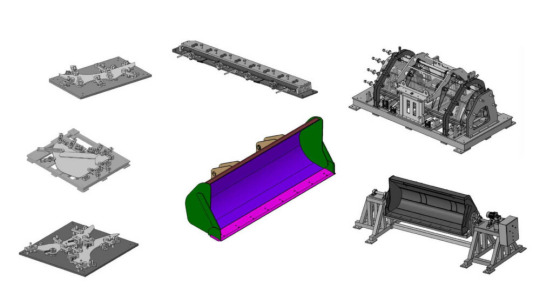

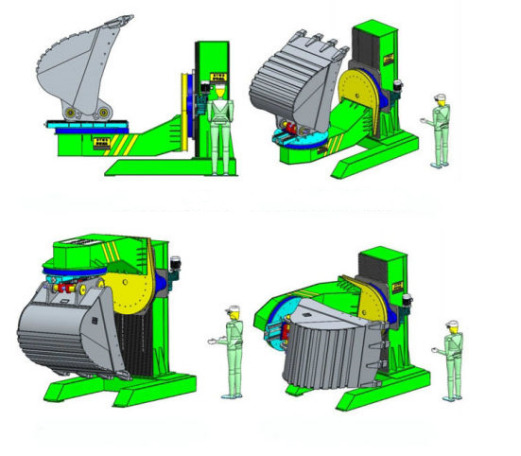

Buckets are often too heavy and large to handle manually, so welding positioners play a critical role in production. Positioners are used to:

Proper clamping is essential to secure the bucket during welding, given its weight and irregular shape. A well-designed fixture setup ensures stability, accuracy, and repeatability.

Clamping Equipment:

To ensure accurate positioning and stability, custom fixtures are designed based on the bucket’s dimensions and shape. The fixture should:

Hold the Bucket Firmly: Prevent movement during welding to ensure consistent weld quality.

Allow Access to Welding Points: Fixtures are designed to allow welding tools to reach all necessary areas without obstruction.

Be Adjustable: Since buckets vary in size and shape, fixtures often have adjustable components to accommodate different models.

Steps to Fabricate Fixtures:

1. Design: Create a fixture design that suits the bucket’s dimensions and allows sufficient access to weld joints.

2. Material Selection: Use durable materials like steel to withstand the heat and force applied during welding.

3. Testing and Adjustment: Test the fixture with a sample bucket, making adjustments to ensure stability and alignment.

Once the bucket is clamped securely, welding proceeds with attention to several key elements:

Welding Sequence: Start with more rigid sections to avoid warping and distortion, often beginning with the base plate and moving to other parts.

Multiple Passes: Some joints require multiple weld passes to achieve the necessary strength.

Pre- and Post-Heat Treatment: Depending on the material, heat treatment may be required to improve weld penetration and reduce residual stresses.

Inspection and Quality Control: Post-weld inspection techniques, such as ultrasonic testing and dye penetrant inspection, identify any flaws or weaknesses in the weld.

CNC Plasma Cutting Machine: For precise cutting of bucket components.

Bevel Milling Machine: Prepares edges for a cleaner, stronger weld.

Plate Bending Machine: Forms the bucket shape by bending steel plates.

Boring Machine: Drills accurate holes in high-stress areas for components like mounting pins.

After welding and assembly, each bucket undergoes rigorous quality checks, focusing on:

Weld Integrity: Inspection methods include X-ray or ultrasonic testing to detect any internal defects.

Strength Tests: Testing includes applying loads to critical points to confirm durability.

Dimensional Accuracy: Ensures the bucket fits precisely on the excavator and meets design specifications.

Surface Finish: Sandblasting and painting improve resistance to rust and wear.