Industrial Welding Equipment CE Certified Welding Positioner

The welding positioner is an essential tool in the field of welding automation, designed to enhance welding productivity and quality by allowing precise control over the workpiece positioning. It is widely used in various industrial applications, including:

– Manufacturing: Ideal for welding components in the automotive, aerospace, and heavy machinery industries.

– Construction: Useful in welding structural components, pipes, and beams.

– Oil and Gas: Suitable for welding pipelines, flanges, and fittings.

– Power Generation: Employed in the fabrication of pressure vessels, wind towers, and other power generation equipment.

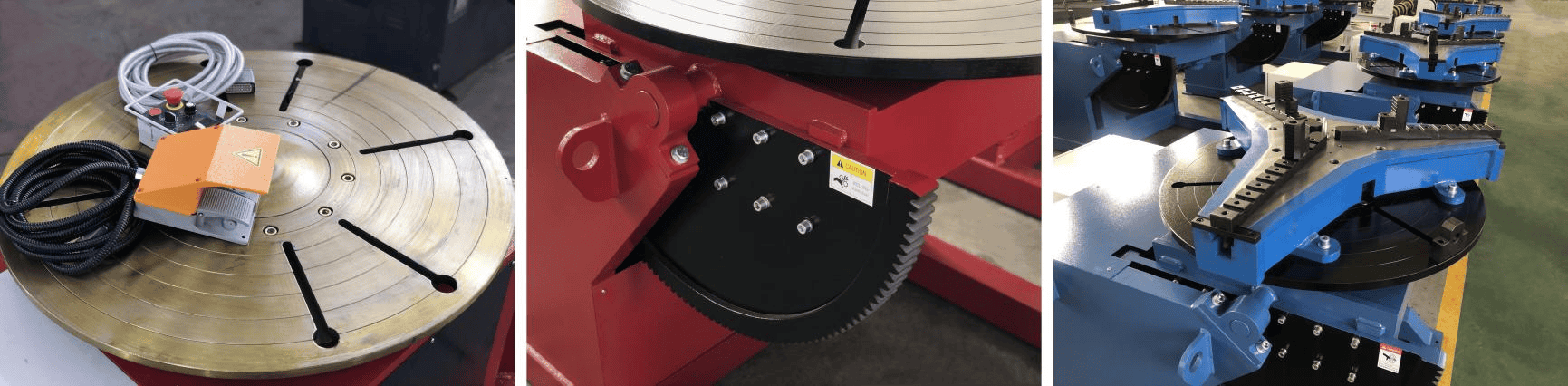

Welding Positioner Machine Construction

The welding positioner is constructed with robust materials to ensure stability and durability. Key components include:

– Rotary Table: The main platform where the workpiece is mounted. It can rotate 360 degrees and tilt to various angles for optimal positioning.

– Base: Provides a stable foundation and can be bolted to the floor for added security.

– Tilting Mechanism: Allows the table to tilt to different angles, providing flexibility in positioning the workpiece for welding.

– Control System: An advanced control panel for adjusting rotation speed, tilt angle, and other parameters to ensure precise control.

– Clamping System: Secures the workpiece firmly to the rotary table, preventing movement during welding.

Detailed Description Of The Welding Positioner

The welding positioner is designed to improve the efficiency and quality of welding operations by providing stable and precise control over the workpiece. Key features include:

– High Load Capacity: Capable of handling heavy workpieces, making it suitable for various industrial applications.

– Adjustable Positioning: The table can rotate and tilt to multiple angles, allowing for optimal welding positions and access to difficult-to-reach areas.

– Precision Control: The control system allows for precise adjustments to rotation speed and tilt angle, ensuring consistent weld quality.

– Safety Features: Includes overload protection and emergency stop functions to ensure safe operation.

– Durability and Stability: Constructed from high-quality materials to withstand harsh industrial environments and provide long-lasting performance.

Welding positioners are widely used in various industries.

Pipeline Fabrication:

– Application: Welding flanges and fittings onto pipelines.

– Example: In an oil and gas facility, the positioner is used to hold and rotate large diameter pipes, making it easier for welders to access and weld all sides of the pipe.

Automotive Manufacturing:

– Application: Welding automotive frames and chassis.

– Example: In an automotive plant, the positioner is used to rotate and tilt the chassis to provide optimal angles for welding, ensuring consistent and high-quality welds.

Aerospace Industry:

– Application: Welding aircraft components.

– Example: In an aerospace manufacturing facility, the positioner is used to precisely position aircraft parts, ensuring accurate and high-quality welds for critical components.