.png)

.png)

.png)

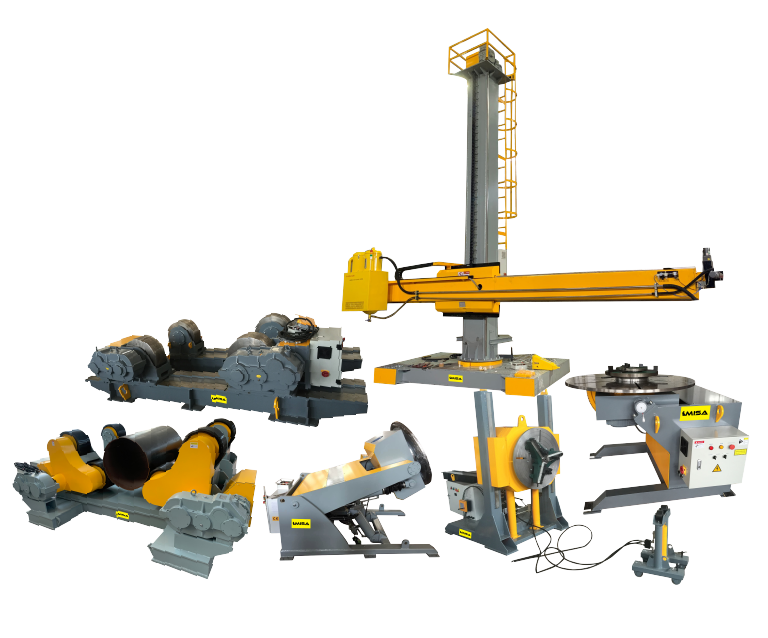

Seamless Rotation for Perfect Welds – Reliable, Efficient, Built to Last.

Extend Your Reach – Advanced Welding Manipulators for Superior Control.

Position with Precision – Achieve Optimal Welding Angles Every Time.

Effortless Turning, Maximum Stability – The Perfect Base for Welding Excellence.

From welding rotators, turning rolls, welding manipulators, to positioning equipment, MISA offers a complete lineup designed to maximize productivity and ensure precision. Trusted by leading industries worldwide, our solutions have earned a reputation for excellence. With a commitment to quality and innovation, we empower clients globally to tackle complex welding tasks with confidence and consistent efficiency.

With decades of expertise, MISA specialize in precision-engineered welding and positioning solutions trusted by industries around the world. Our commitment to quality drives us to innovate and deliver equipment that meets the highest standards, empowering clients globally to achieve excellence in every project.

CORTE & CONFORMACAO DE METAIS (CCM) is the largest metal forming, cutting and welding industry exhibition in Brazil and even in South America.

SCHWEISSEN & SCHNEIDEN is the meeting place for experts and top decision makers of the joining, cutting...

FABTECH 2025 is in October 8-11 at McCormick Place in Chicago. #FABTECH2025 FABTECH is North America’s largest...